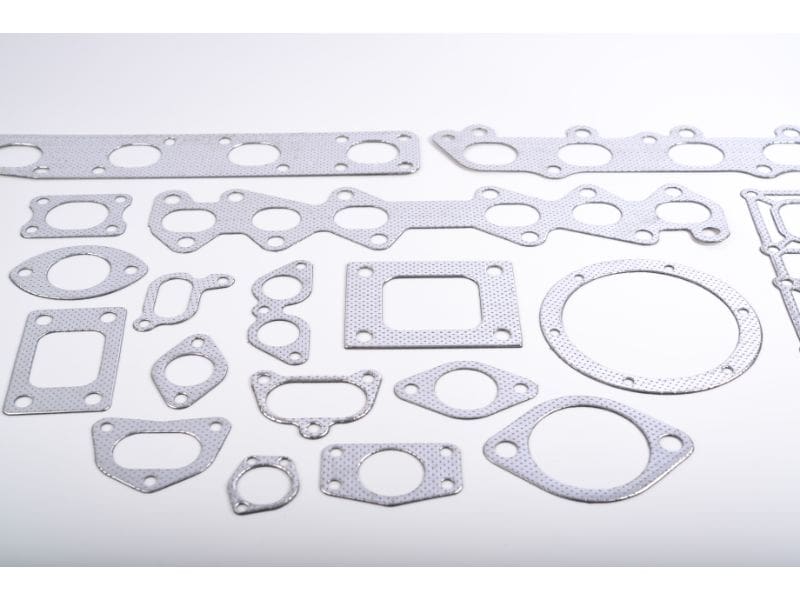

Summary. Stephens Gaskets, based in the West Midlands, specialises in bespoke laser cutting gasket services. We focus on precision and detail to provide unparalleled results. Initially, understanding customer requirements is paramount, leading to a comprehensive design process. Using advanced equipment, we efficiently produce intricate gaskets from various materials. As leaders in laser cutting in the West Midlands, we offer competitive prices and a commitment to excellence in evolving laser technologies.

At Stephens Gaskets, we offer bespoke laser cutting in the West Midlands. Our laser cutting gasket services achieve flawless results through a new level of accuracy and detail that cannot be attained elsewhere. But, what is the process that we undergo to provide such results? Continue reading to learn about our laser cutting methods; from design to production.

Always abiding by our customers’ needs, we continuously develop our processes. Consequently, ensuring we’re delivering excellence in our service and products. Laser cutting enables us to meet consumer demands, especially when a business requires large batch quantities. Additionally, due to industries continuously evolving, we can upkeep the quality requirements in our products.

What are the initial steps in our laser cutting services?

Before we begin the design stages of our laser cutting gasket services, we must gain an understanding of your exact needs. Depending on the project, the requirements can vary. This could be in terms of the batch number, as well as the shape and size of the gaskets themselves.

As we provide a completely bespoke service, we must learn your needs so that we can meet them exactly. We do this through an initial consultation that asks you the relevant questions to make sure we’re prepared for the project. By covering all grounds, our services begin and stay on track; therefore, allowing you to meet your deadlines too.

Below is an insight into the steps post-consultation for our laser cutting services in the West Midlands.

The Design Process

Our laser cutting gasket services begin through a comprehensive design process. This system is determined by the dimensions, material and other special requirements that were agreed upon during the consultation. Once we have these factors in place, we can plan your laser cutting run. Initially, we will produce a prototype that ensures you’re completely happy before we begin production.

The Production

Once you have confirmed that you’re satisfied, we will proceed with our laser-cutting process. Using state-of-the-art equipment, our controlled lasers cut custom and complex profiles in both polymers and sheets of metal. The efficiency and intricacy of this production method are second to none.

The laser cutters rely upon excellent software that assures complete control, even in the most complex cases. This not only supports the seamless results but also the maximum gaskets that can be cut from a single sheet of material.

Gasket Laser Cutting from Stephens Gaskets

Looking for gasket laser cutting services in the West Midlands? We strive to deliver our customers a completely reliable and trustworthy service from start to finish. Promising competitive pricing too, our team has led us to become one of the most acclaimed gasket manufacturers in the nation. As laser cutting continues to evolve and progress, we guarantee our customers a service that translates this.

If you’d like to find out more about what we can achieve for your business through our laser cutting gasket services, get in touch with us today. Call us at 0121 544 5808 or via email at sales@stephensgaskets.co.uk.