Laser Cutting for Specific Materials

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for Laser Cutting

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

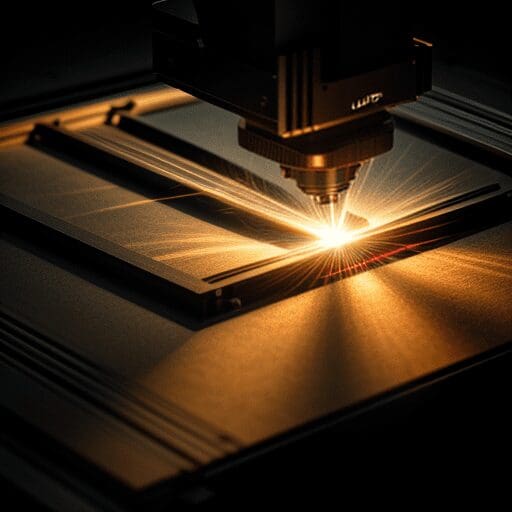

Advantages of Laser Cutting for Stainless Steel

At Stephens Gaskets, we specialise in laser cutting a variety of materials, with a particular focus on stainless steel. Our advanced laser cutting technology offers numerous advantages, including clean edges, minimal heat distortion, and high-speed processing. These benefits make our laser cutting services ideal for industries that commonly use stainless steel, such as medical, aerospace, and food processing.

Our Stainless Steel Laser Cutting services offer clean edges, minimal heat distortion, and high-speed processing. These features make it an ideal choice for industries such as medical, aerospace, and food processing.

. Laser cutting stainless steel offers several distinct advantages that enhance the quality and efficiency of production processes.

Clean Edges

One of the primary benefits of laser cutting stainless steel is the ability to produce clean, precise edges. Our laser cutting technology ensures that each cut is smooth and burr-free, reducing the need for additional finishing work. This precision is particularly important for applications where edge quality is critical, such as in medical devices and aerospace components.

Minimal Heat Distortion

Laser cutting utilises a focused beam of light to cut materials, which minimises the heat affected zone (HAZ) around the cut. This results in minimal heat distortion and maintains the structural integrity of the stainless steel. For industries that require exacting standards, such as aerospace and medical, maintaining the material’s properties is essential.

High-Speed Processing

Our laser cutting equipment is designed for high-speed processing, allowing us to cut stainless steel quickly and efficiently. This rapid processing capability not only reduces production time but also lowers costs, making it a cost-effective solution for high-volume orders and time-sensitive projects.

Applications in Various Industries

Stainless steel is a preferred material in numerous industries due to its strength, corrosion resistance, and aesthetic appeal. Our laser cutting services cater to a wide range of applications, ensuring that each industry benefits from our precision and expertise.

Medical Industry

Medical-Grade Stainless Steel Laser Cutting: The medical industry demands the highest levels of precision and cleanliness. Our laser cutting services for medical-grade stainless steel ensure that components meet stringent hygiene and quality standards. Typical applications include surgical instruments, medical implants, and diagnostic equipment.

Advantages:

- Precision and Accuracy: Laser cutting allows for the creation of intricate and precise components required for medical applications.

- Clean Edges: The clean cuts reduce the risk of contamination, which is crucial for medical devices.

- Customisation: We can produce custom shapes and sizes to meet specific medical requirements.

Aerospace Industry

Aerospace Stainless Steel Laser Cutting Solutions: The aerospace industry relies on stainless steel for its strength and durability. Our laser cutting services provide the precision needed for complex aerospace components, ensuring they meet the industry’s exacting standards. Applications include structural components, engine parts, and fastening systems.

Advantages:

- High Precision: Our laser cutting technology ensures that each part meets tight tolerances and specifications.

- Minimal Heat Distortion: Maintaining the material’s integrity is critical for aerospace applications, and our laser cutting minimises heat distortion.

- Efficiency: High-speed processing allows for faster production of aerospace components, reducing lead times.

Food Processing Industry

Food-Grade Stainless Steel Laser Cutting Specialists: Stainless steel is the material of choice in the food processing industry due to its corrosion resistance and hygienic properties. Our laser cutting services for food-grade stainless steel ensure that components are safe, durable, and meet industry standards. Applications include machinery parts, cutting tools, and processing equipment.

Advantages:

- Hygienic Cuts: Clean, precise cuts ensure that there are no burrs or rough edges that could harbour bacteria.

- Corrosion Resistance: Stainless steel’s natural resistance to corrosion makes it ideal for food processing environments.

- Customisation: We can produce parts that meet the specific needs of food processing equipment manufacturers.

Quality Control and Precision

Ensuring the highest quality and precision is a core part of our laser cutting services at Stephens Gaskets. Our quality control processes are designed to maintain strict standards, guaranteeing that each stainless steel component meets your exact requirements.

Rigorous Inspection

Every stainless steel part we produce undergoes rigorous inspection to verify its accuracy and quality. We use advanced measurement tools to ensure that each component meets the specified dimensions and tolerances. This meticulous attention to detail ensures that our clients receive parts that are ready for immediate use.

Consistent Quality

Our laser cutting technology provides exceptional consistency and repeatability, which is crucial for large production runs. Whether you need a small batch of prototypes or a high-volume order, you can count on Stephens Gaskets for consistent quality and precision in every part.

Client Collaboration

We believe in working closely with our clients to ensure their complete satisfaction. From initial design consultation to final production, our team collaborates with you to understand your specific needs and deliver parts that exceed your expectations.

Examples of Laser-Cut Stainless Steel Components

Our expertise in laser cutting stainless steel is demonstrated through various successful projects across multiple industries. Here are some examples of how our precision laser cutting services benefit different sectors:

Surgical Instruments

We produce high-precision surgical instruments with clean, precise edges and intricate designs. Our laser cutting services ensure that each instrument meets the strict hygiene and quality standards required in the medical industry.

Aerospace Fasteners

Our laser-cut stainless steel fasteners are used in aerospace applications where strength and precision are paramount. The minimal heat distortion and high precision of our cuts ensure that these components perform reliably under demanding conditions.

Food Processing Equipment

We manufacture custom parts for food processing equipment, ensuring that each component is hygienic, corrosion-resistant, and meets industry standards. Our laser cutting services enable the production of parts with smooth, clean edges, essential for maintaining food safety.

Conclusion

Stephens Gaskets’ expertise in laser cutting stainless steel offers unmatched precision, quality, and efficiency across various industries. Whether you require medical-grade components, aerospace solutions, or food-grade parts, our laser cutting services ensure that each project meets the highest standards.

Need Guidance on Laser Cutting?

Our comprehensive expertise in laser cutting for specific materials positions us as a trusted partner across industries. Whether you need stainless steel laser cutting, food-grade laser cutting services, or aerospace-grade laser cutting solutions, we deliver precision, efficiency, and quality every time. Stephens Gaskets is a leading supplier of high-quality laser cutting. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Laser Cutting and how we can help you with your next project.