Summary. Our custom laser cutting service at Stephens Gaskets excels in laser cutting silicone rubber, producing bespoke gaskets suitable for various applications and industries. This process involves precise, controlled lasers for cutting rubber sheets, ensuring accuracy and optimal performance. Renowned for our efficiency and competitive pricing, our service offers quick turnaround times and precise results, making it ideal for businesses needing high-quality rubber gaskets for diverse manufacturing needs.

Laser cutting is one of the most effective manufacturing processes for shims and foil. Through specialised and controlled lasers, we are able to produce bespoke laser cut gaskets suitable for a range of applications in various industries. Our custom laser cutting service allows us to achieve impeccable results for optimum performance. Continue reading this article to find out more about how our laser experts attain such immaculate results. As well as, finding the answers to all of our most-asked questions on laser cutting silicone rubber.

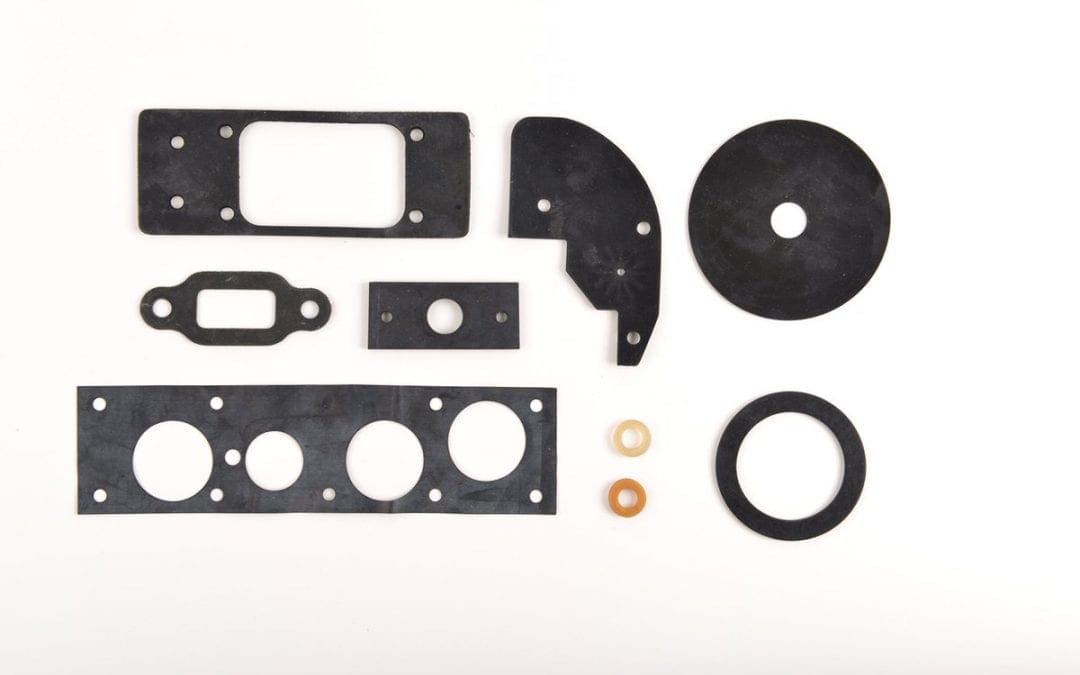

Laser Cutting Silicone Rubber

So, how does laser cutting work? When cutting silicone rubber with laser, there is a strict process that all machine operators must adhere to. While ensuring safety measures in place, they use a pre-determined guide that is accurately shaped and sized to meet the project’s needs. Then, powerful and contained lasers, cut through the sheet of rubber, allowing for complete accuracy throughout.

The same system applies to laser cutting other materials such as metal or polymer, ensuring that each batch’s guidelines are followed. This type of customisation for gaskets and shims allows for both affordability and a quick turnaround.

Why Use Rubber Gaskets?

Rubber is one of the most robust materials for gaskets. Its next-level tensile strength makes this substance ideal for heavy machinery in a variety of industries. The material also holds excellent resistance to high temperatures, not to mention it bares anti-tearing and compression capabilities.

Additionally, rubber laser cut gaskets offer electricity insulation, making this material highly sought after. When combined with state of the art laser cutting, you will ensure that your applications are given the finest quality components.

How Much Are Laser Cut Gaskets?

People often ask, how much are our laser cut gaskets? And we’re proud to say that our cheap laser cutting service meets competitive prices nationally. Due to sizing, quantities and special requirements for each project, we will assess your needs and deliver you a bespoke quote in no time at all.

How Long Does Laser Cutting Take?

When laser cutting silicone rubber, it is always a quick turnaround. Depending on the size of the batch, the rapid procedure uses extremely advanced technology. Therefore, giving you the best results in the best time possible; especially compared to other cutting services.

The Results of Laser Cutting

What are the results of laser cutting, you ask? Due to the intricate guidelines that you will provide us with prior to the process, we can guarantee precision for all of your rubber gaskets. Laser cutting, as you know, sets a new standard for precision within gasket and shim production. Using state of the art laser cutting machinery, we can accomplish all thickness and size requirements.

Our batch laser cutting service ensures that your business can continue operating smoothly and efficiently.

Custom Laser Cutting Service at Stephens Gaskets

Here at Stephens Gaskets, we are proud to provide rubber laser cut gaskets. As one of the leading laser cutting companies in the UK, we are known for our astounding service from concept to completion. If you’re a manufacturing business that requires laser cutting specialists for your applications, get in touch with us today on 0121 544 5808. Offering worldwide shipping, we promise a seamless service throughout.