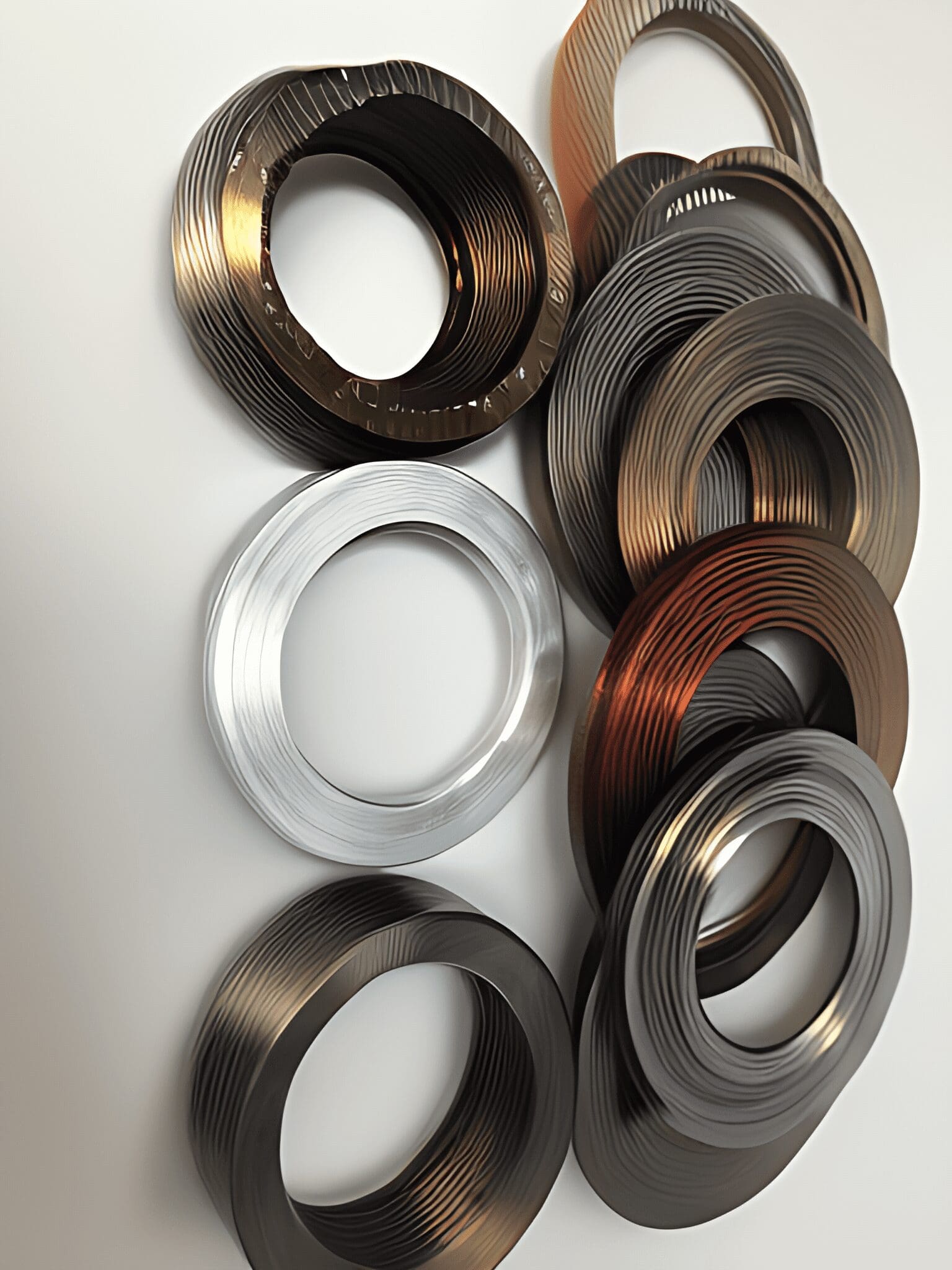

Keyway Shims

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for Keyway Shims

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Global Leaders in Shim Solutions

As a trusted provider of shim solutions, we serve OEMs and businesses globally.

At Stephens Gaskets, we are a proud supplier of Keyway Shims that can be custom made to meet the needs of our customers. Moreover, our experienced team is equipped with the latest technology and machinery to manufacture high-quality Keyway Shims that are built to last.

If you’re seeking high-quality Keyway Shims with a quick turnaround, look no further.

Our reputation as the best in the business is well-deserved. With over 70 years of experience delivering top-notch products that meet both your budget and timeline. Our commitment to quality and efficiency is unwavering.

What are Keyway Shims?

Keyway shims are thin, precisely engineered pieces of material, typically made from stainless steel, brass, or plastic, used to fill gaps or spaces in keyways. A keyway is a slot or groove cut into a shaft and a corresponding part, like a hub or gear, which accommodates a key. The key locks these parts together, allowing for torque transmission while preventing relative motion.

At Stephens Gaskets, we understand that keyway shims are primarily used to adjust the fit and alignment of the key within the keyway, ensuring a secure and accurate connection between components. They are indispensable in maintaining the integrity and efficiency of mechanical systems by preventing relative motion and ensuring proper torque transmission.

What are the benefits of Keyway Shims?

Keyway shims offer several benefits that enhance the performance and longevity of mechanical systems:

Improved Alignment

- Precision Fit: Ensures components are properly aligned, reducing wear and improving performance.

- Vibration Reduction: Proper alignment reduces vibrations, leading to smoother operation and less wear on components.

Extended Machinery Life

- Wear Prevention: Prevents premature wear of keys and keyways by filling gaps and ensuring a tight fit.

- Damage Reduction: Minimising movement and misalignment protects other components from damage, extending machinery lifespan.

Enhanced Performance

- Secure Connection: Ensures stable connections between shafts and attached components, allowing for efficient torque transmission.

- Consistent Operation: Improved alignment and reduced wear lead to more reliable machinery performance.

Cost Savings

- Reduced Maintenance: Better alignment and less wear result in less frequent maintenance and part replacements, saving on downtime and costs.

- Lower Repair Costs: Preventing damage to key components reduces the need for expensive repairs.

Versatility

- Customisation: Available in various sizes and materials, allowing for customisation to meet specific application requirements.

- Material Options: Depending on the operating environment, shims can be selected from materials like stainless steel, brass, or plastic.

Ease of Installation

- Simple Solution: Provides an easy and effective way to address alignment and fit issues without major modifications to the machinery.

- Quick Adjustment: Allows for quick adjustments and fine-tuning during assembly or maintenance.

What are the applications of Keyway Shims?

Keyway shims are widely used in various industries due to their crucial role in maintaining precise alignment and secure connections. Key industries include:

Machinery and Equipment:

Ensures alignment in manufacturing and assembly lines, reducing wear in rotating equipment and conveyors.

Automotive Industry

Critical for aligning engine components and transmission systems, ensuring efficient power transfer and reducing vibrations.

Aerospace

Maintains precise alignment in aircraft engines and landing gear systems, crucial for safety and performance.

Marine Industry

Ensures proper alignment in propulsion and steering mechanisms, enhancing performance and reducing wear.

Manufacturing

Used in assembly lines and robotics for precise fitting and alignment of parts.

Pumps and Compressors

Aligns shafts and impellers, improving efficiency and reducing maintenance needs.

Heavy Machinery

Maintains alignment in construction and mining equipment, extending operational life.

Looking for a Keyway Shims Supplier?

Stephens Gaskets is a leading supplier of high-quality Keyway Shims. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Keyway Shims and how we can help you with your next project.

Industry-Specific Materials for Keyway Shims

In the manufacturing industry, materials for keyway shims are chosen based on properties such as durability, corrosion resistance, and specific application requirements. Here are some industry-specific materials commonly used for keyway shims:

- Stainless Steel (304 and 316): Excellent corrosion resistance and high strength. Used in food processing, pharmaceuticals, and chemical manufacturing.

- Brass: Good corrosion resistance, excellent machinability, and conductivity. Ideal for electronics, plumbing, and automotive industries.

- Carbon Steel: High strength, wear resistance, and cost-effective. Used in heavy machinery, automotive, and general engineering.

- Aluminium: Lightweight, corrosion-resistant, and easy to machine. Suitable for aerospace, automotive, and electronics industries.

- Plastic (Nylon, Polyethylene, PTFE): Lightweight, chemical-resistant, low friction, and non-conductive. Used in electronics, packaging, and food processing.

- Bronze: Good wear resistance, low friction, and machinability. Suitable for bearings and bushings in industrial machinery.

- Copper: Excellent electrical and thermal conductivity, good corrosion resistance. Used in electrical equipment and heat exchangers.

- Phosphor Bronze: High strength, good corrosion resistance, and fatigue resistance. Ideal for springs and bearings.

- Titanium: High strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Used in aerospace, medical devices, and high-performance engineering.

- Composite Materials: High strength, lightweight, and customizable properties. Used in advanced manufacturing applications like aerospace and sports equipment.

Issues with Keyway Shims and how Stephens Gaskets Addresses Them

While keyway shims are essential, they come with certain challenges. Here are some common pain points and how Stephens Gaskets addresses them:

Installation Complexity

- Precision Required: Ensuring proper alignment is crucial. Solution: Stephens Gaskets provides high-quality, precisely manufactured shims and offers expert installation guidance to ensure accurate alignment.

- Time-Consuming: Inserting and adjusting shims can be time-consuming. Solution: Our efficient installation techniques and high-quality products simplify the process, saving you time and effort.

Wear and Tear

- Material Degradation: Shims can wear out over time. Solution: Stephens Gaskets uses durable materials and provides regular inspection and replacement services to ensure longevity.

- Environmental Factors: Exposure to harsh conditions can degrade shims. Solution: We offer shims made from materials specifically designed to withstand harsh environmental conditions, ensuring long-term reliability.

Inventory Management

- Variety of Sizes: Keeping various sizes in stock can be challenging. Solution: Stephens Gaskets maintains a well-organised inventory and collaborates with clients to ensure timely availability of needed shims.

- Custom Shims: Custom shims can have longer lead times and higher costs. Solution: Our advanced manufacturing capabilities allow us to produce custom shims efficiently and cost-effectively.

Cost Considerations

- Material Costs: High-quality materials can be expensive. Solution: Stephens Gaskets balances cost with performance and longevity, offering competitive pricing for high-quality shims.

- Frequent Replacements: Regular replacement can be costly. Solution: Our durable materials and regular maintenance schedules help reduce the frequency of replacements, saving you money in the long run.

Performance Issues

- Misalignment Risks: Improper fitting can cause misalignment. Solution: Stephens Gaskets ensures accurate installation with high-quality shims and expert guidance to minimise misalignment risks.

- Vibration and Noise: Inadequate placement can cause vibrations and noise. Solution: Our precisely manufactured shims reduce vibrations and noise, improving machinery performance.

Maintenance Challenges

- Accessibility: Some machinery components can be hard to access. Solution: Stephens Gaskets designs machinery for easier access to keyway shims and provides detailed installation instructions.

- Inspection: Regular inspections are necessary. Solution: We implement routine maintenance schedules to ensure your shims remain in optimal condition.

Compatibility Issues

- Material Mismatch: Using the wrong material can cause issues. Solution: Stephens Gaskets carefully selects materials based on application requirements, ensuring compatibility and performance.

- Dimensional Variability: Inconsistent manufacturing tolerances can cause fit issues. Solution: Our high-precision manufacturing processes ensure consistent and accurate shims.

Training and Expertise

- Skilled Labour: Proper installation requires skilled labour. Solution: Stephens Gaskets provides comprehensive training for personnel to ensure proper installation and maintenance.

- Training Costs: Training can be costly and time-consuming. Solution: We invest in quality training programs to ensure long-term benefits, offering support and guidance throughout the process.

FAQs

What are keyway shims, and why are they important?

Keyway shims are thin, precisely engineered pieces of material used to fill gaps or spaces in keyways. They are crucial for ensuring proper alignment and secure connections in mechanical systems.

How do keyway shims improve machinery performance and longevity?

By ensuring a precise fit and alignment, keyway shims reduce wear and tear, minimise vibrations, and prevent damage to machinery components, thereby extending their lifespan.

What problems can occur if keyway shims are not used or are improperly installed?

Improper installation or absence of keyway shims can lead to misalignment, increased wear, vibrations, and potential failure of mechanical systems.

What materials are commonly used for keyway shims, and what are their benefits?

Common materials include stainless steel, brass, plastic, and aluminium. Each material offers unique benefits such as corrosion resistance, electrical conductivity, and lightweight properties.

What industries typically use keyway shims, and for what applications?

Industries like automotive, aerospace, manufacturing, and marine use keyway shims for applications such as engine alignment, transmission systems, assembly lines, and propulsion systems.

How do I choose the right material for keyway shims for my specific application?

Consider the operating environment, load and wear requirements, and specific needs of your application. Our material guide can help you make an informed decision.

What are the advantages of using custom-made keyway shims over standard ones?

Custom-made shims are tailored to fit specific dimensions and requirements, ensuring optimal performance and reliability.

How can keyway shims reduce maintenance costs and downtime in my machinery?

By providing precise alignment and reducing wear and tear, keyway shims minimise the need for frequent maintenance and part replacements, thus reducing downtime and costs.

Are there any case studies or success stories of companies that improved their operations using keyway shims?

Yes, we have numerous success stories where our keyway shims have significantly improved machinery performance and reliability in various industries. Contact Us for detailed case studies.

What factors should be considered when selecting the size and thickness of keyway shims?

Consider the gap size, load-bearing requirements, and specific application needs. Our experts can help you determine the right size and thickness for your shims.

Why should I choose Stephens Gaskets for my keyway shim needs?

Stephens Gaskets offers high-quality, precisely manufactured keyway shims with a commitment to customer satisfaction and industry expertise.

Need Guidance on Keyway Shims?

Stephens Gaskets is a leading supplier of high-quality Keyway Shims. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Keyway Shims and how we can help you with your next project.