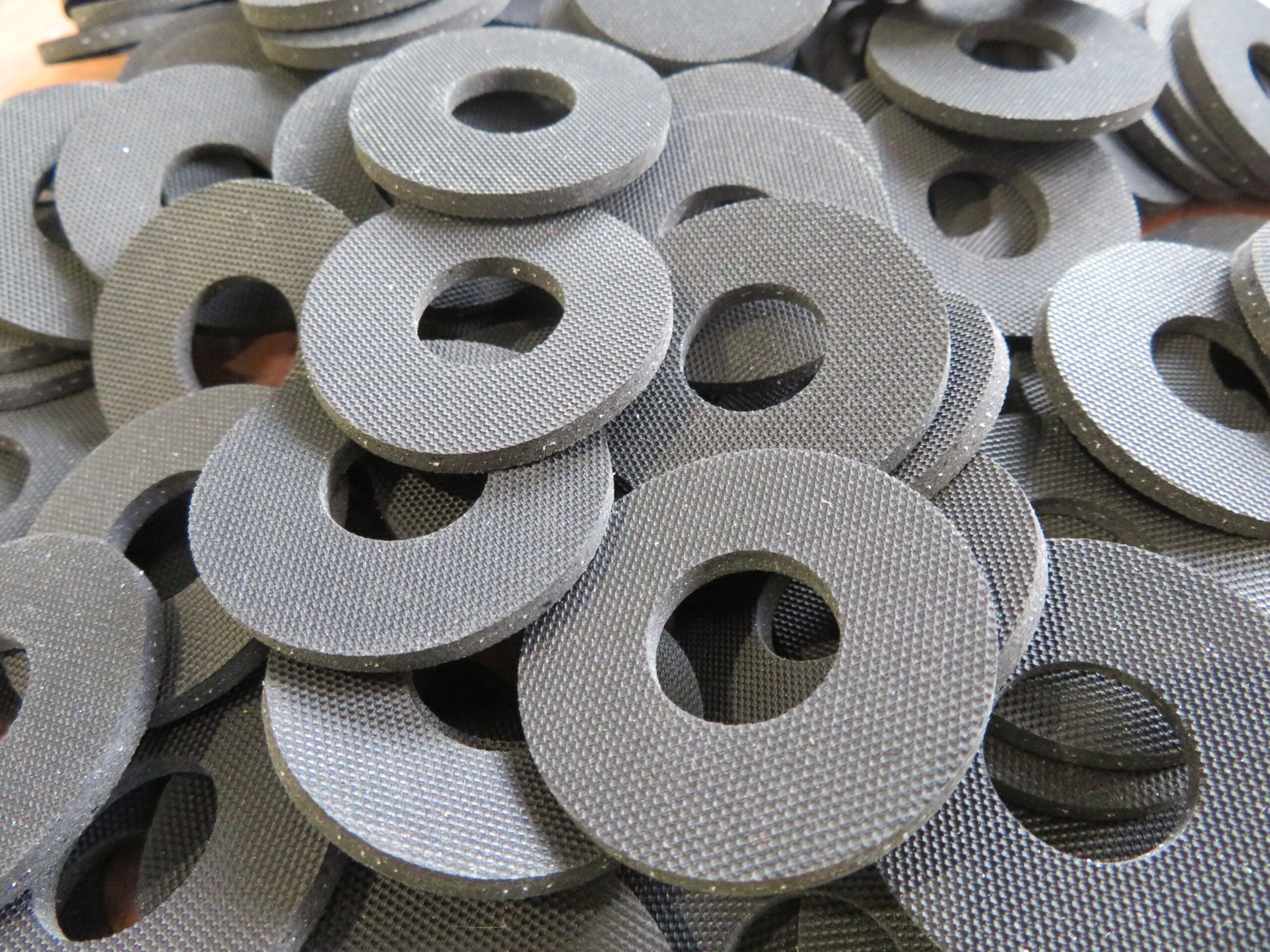

Insertion Natural Rubber

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for Insertion Natural Rubber

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Global Leaders in Shim Solutions

As a trusted provider of shim solutions, we serve OEMs and businesses globally.

At Stephens Gaskets, we are a proud supplier of Insertion Natural Rubber that can be custom made to meet the needs of our customers. Moreover, our experienced team is equipped with the latest technology and machinery to manufacture high-quality Insertion Natural Rubber that is built to last.

If you’re seeking high-quality Insertion Natural Rubber with a quick turnaround, look no further.

Our reputation as the best in the business is well-deserved. With over 70 years of experience delivering top-notch products that meet both your budget and timeline. Our commitment to quality and efficiency is unwavering.

What is Insertion Natural Rubber?

Insertion natural rubber is a type of natural rubber material that has been reinforced with fabric or other materials to enhance its strength and durability. Here’s a detailed breakdown:

Characteristics of Insertion Natural Rubber:

Composition: Made from natural rubber, which is harvested from rubber trees, with added fabric inserts (typically cotton, polyester, or nylon).

Reinforcement: The fabric layers are inserted during the manufacturing process, which significantly increases the rubber’s resistance to tearing and stretching.

Durability: Enhanced wear resistance and improved mechanical properties compared to standard natural rubber.

Flexibility: Maintains the natural rubber’s excellent elasticity and flexibility.

Strength: Provides additional tensile strength and dimensional stability.

Applications of Insertion Natural Rubber:

Gaskets and Seals: Used in applications where robust sealing is required, such as in automotive, aerospace, and industrial machinery.

Industrial Belting: Ideal for conveyor belts and other industrial belting applications that require added strength and longevity.

Vibration Damping: Used in anti-vibration mounts and pads, as the fabric reinforcement helps in absorbing and mitigating vibrations more effectively.

Protective Linings: Commonly used as linings for tanks and pipes to protect against abrasion and wear.

Advantages of Using Insertion Natural Rubber:

Enhanced Strength: The fabric reinforcement provides superior strength and durability.

Long-Lasting: Greater resistance to wear and tear leads to a longer lifespan.

Versatility: Suitable for a wide range of applications due to its combined properties of flexibility and strength.

Cost-Effective: Reduces the frequency of replacements and maintenance due to its durability.

Insertion natural rubber is a reliable choice for applications demanding high performance and longevity, combining the best properties of natural rubber with enhanced mechanical strength.

What are the benefits of Insertion Natural Rubber?

Insertion natural rubber offers several benefits due to its unique combination of natural rubber’s properties and the added strength from fabric reinforcement. Here are the key benefits:

Enhanced Strength and Durability:

Increased Tear Resistance: The fabric inserts significantly enhance the rubber’s resistance to tearing, making it suitable for demanding applications.

Improved Tensile Strength: The added layers provide superior tensile strength, allowing the material to withstand higher levels of stress and strain.

Longevity:

Extended Lifespan: With enhanced durability, insertion natural rubber products have a longer service life, reducing the need for frequent replacements.

Reduced Wear and Tear: The reinforced structure is more resistant to wear and abrasion, making it ideal for high-friction environments.

Versatility:

Wide Range of Applications: Suitable for various industrial uses, including gaskets, seals, conveyor belts, and protective linings.

Adaptable to Different Environments: Performs well in both static and dynamic applications, handling both compression and movement effectively.

Cost Effectiveness:

Lower Maintenance Costs: The long-lasting nature of insertion natural rubber reduces maintenance and replacement costs.

Fewer Downtimes: Enhanced durability means less frequent need for repairs or replacements, leading to less operational downtime.

Flexibility & Resistance:

Maintained Elasticity: Despite the added reinforcement, insertion natural rubber retains the natural rubber’s flexibility and elasticity, making it suitable for applications requiring flexibility.

Effective Sealing: The combination of strength and flexibility ensures excellent sealing properties, essential for gaskets and seals.

Vibration & Impact Absorbtion:

Superior Vibration Damping: The reinforced material is effective in absorbing and dampening vibrations, which is beneficial in applications like anti-vibration mounts and pads.

Impact Resistance: Enhanced resilience to impacts, providing protection in applications where shock absorption is critical.

Chemical & Environmental Resistance:

Resistance to Chemicals: Natural rubber itself has good resistance to a variety of chemicals, and the reinforcement can enhance this property.

Weather Resistance: Suitable for use in various environmental conditions, maintaining performance under different weather conditions.

Customizability:

Tailored Solutions: Insertion natural rubber can be customised with different types of fabric inserts (e.g., cotton, polyester, nylon) to meet specific application needs.

Variety of Thicknesses: Available in various thicknesses and configurations to suit different industrial requirements.

What are the applications of Insertion Natural Rubber?

Insertion natural rubber is a versatile material used in various applications due to its enhanced strength, durability, and flexibility. Here are some key applications:

Gaskets and Seals:

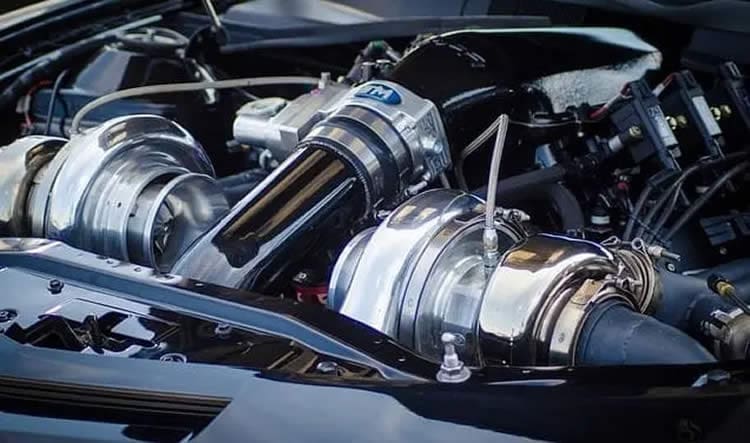

Automotive: Used in engine gaskets, door seals, and other components requiring reliable sealing under pressure and temperature variations.

Industrial Machinery: Effective in sealing joints, preventing leaks, and maintaining pressure in industrial equipment.

Aerospace: Employed in sealing applications that require high durability and resistance to extreme conditions.

Conveyor Belts:

Material Handling: Ideal for conveyor belts in manufacturing plants, warehouses, and distribution centres due to its strength and wear resistance.

Food Industry: Used in food processing conveyor systems where hygiene and durability are critical.

Mining: Suitable for heavy-duty conveyor belts in mining operations where high abrasion resistance is needed.

Vibration Damping and Shock Absorption:

Anti-Vibration Mounts: Used in machinery and equipment to reduce vibration and noise, enhancing operational stability and longevity.

Shock Absorbers: Effective in applications requiring impact resistance, such as protective pads and bumpers.

Protective Linings:

Tanks and Pipes: Used as linings for tanks and pipes to protect against abrasion, corrosion, and chemical exposure.

Chutes and Hoppers: Applied in chutes and hoppers to minimise wear and tear from abrasive materials.

Flooring and Matting:

Industrial Flooring: Used in factories and workshops for durable, non-slip flooring that can withstand heavy foot and machinery traffic.

Sports and Gym Flooring: Provides cushioning and impact resistance in sports facilities and gyms.

Marine Applications:

Dock Fenders: Used in marine environments for dock fenders and bumpers to protect vessels and docks from impact damage.

Seals and Gaskets: Employed in marine equipment and structures that require durable sealing solutions in harsh environments.

Agricultural Applications:

Machinery Parts: Used in various parts of agricultural machinery that require flexible yet durable components.

Animal Housing: Provides durable, non-slip flooring and matting in animal housing facilities.

Construction:

Expansion Joints: Used in construction joints to accommodate movement and prevent cracking in structures.

Building Seals: Effective in sealing windows, doors, and other building components to prevent air and water ingress.

Electrical Applications:

Insulating Mats: Used in electrical installations to provide insulation and protect workers from electric shock.

Cable Protectors: Employed to protect cables from abrasion and environmental damage.

Custom Applications:

Bespoke Components: Can be tailored to specific needs with varying thicknesses, fabric types, and configurations to meet unique industrial requirements.

Prototype Development: Used in developing prototypes that require testing for durability and performance in demanding conditions.

Insertion natural rubber‘s combination of flexibility, strength, and resistance to various environmental factors makes it suitable for a wide range of demanding applications across multiple industries.

Looking for an Insertion Natural Rubber Supplier?

Stephens Gaskets is a leading supplier of high-quality Insertion Natural Rubber. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Insertion Natural Rubber and how we can help you with your next project.

What are the industry specific (manufacturing) materials used for Insertion Natural Rubber?

Insertion natural rubber is commonly used in manufacturing due to its enhanced properties achieved through the incorporation of reinforcing materials. The specific materials used for insertion and their industry applications include:

Engine Gaskets: Reinforced with cotton or polyester for sealing applications that endure temperature fluctuations and mechanical stress.

Hoses and Seals: Utilised in coolant, fuel, and air hoses, offering flexibility and strength with polyester or nylon reinforcement.

Aerospace Industry:

Sealing Systems: Kevlar or glass fibre reinforced insertion rubber used in seals and gaskets for high-strength and temperature-resistant applications.

Vibration Dampers: Employed in anti-vibration applications to protect sensitive aerospace components from mechanical vibrations.

Manufacturing and Material Handling:

Conveyor Systems: Polyester or nylon reinforced belts used for transporting materials in manufacturing plants and warehouses, providing durability and efficiency.

Protective Linings: Nylon or glass fibre reinforced linings in chutes and hoppers to resist wear from abrasive materials.

Heavy Machinery:

Industrial Belts: Nylon or steel wire reinforcement in belts for heavy machinery, offering maximum strength and resistance to heavy loads and harsh conditions.

Shock Absorbers: Used in machinery mounts and pads, reinforced with steel wire or glass fibre for excellent shock absorption and durability.

Construction Industry:

Expansion Joints: Polyester or nylon reinforced rubber used in expansion joints to accommodate building movements and prevent cracking.

Sealing Solutions: Utilised in seals for windows, doors, and other construction components, offering flexibility and durability.

Food and Beverage Industry:

Conveyor Belts: Cotton or polyester reinforced belts used in food processing, providing a hygienic and durable solution for material handling.

Electrical Industry:

Insulating Mats: Used in electrical installations, reinforced with glass fibre for enhanced insulation properties and durability.

Cable Protectors: Polyester or nylon reinforced protectors used to safeguard cables from abrasion and environmental damage.

Insertion natural rubber’s adaptability to various reinforcing materials makes it a versatile and valuable material in many industrial and manufacturing applications, offering tailored solutions to meet specific performance requirements.

What are common issues of Insertion Natural Rubber?

While insertion natural rubber has numerous advantages and applications, it also has certain pain points or drawbacks that potential users should consider. Here are some of the key pain points:

- Cost:

Higher Initial Cost: The addition of reinforcing materials such as polyester, nylon, or Kevlar increases the production cost compared to standard natural rubber.

Cost of Customization: Customising insertion natural rubber to meet specific requirements (e.g., specific fabric inserts, thicknesses) can further raise costs.

- Weight:

Increased Weight: The addition of reinforcing materials can make the product heavier, which might be a disadvantage in applications where weight is a critical factor.

- Flexibility and Elasticity:

Reduced Flexibility: The reinforcing materials can reduce the overall flexibility and elasticity of the natural rubber, making it less suitable for applications that require high levels of stretch and bendability.

Stiffness: Depending on the type and amount of reinforcement, the rubber may become stiffer, which can be a limitation in applications needing a softer, more pliable material.

- Processing and Handling:

Complex Manufacturing Process: The insertion process involves additional manufacturing steps, which can complicate production and require specialised equipment.

Handling Challenges: The increased stiffness and weight can make handling and installation more challenging compared to standard natural rubber.

- Compatibility:

Material Compatibility: Not all reinforcing materials are compatible with all types of natural rubber applications, which can limit the use of insertion natural rubber in certain environments or with specific chemicals.

Environmental Resistance: While reinforced, insertion natural rubber may still have limitations in extreme chemical, thermal, or UV exposure environments compared to synthetic alternatives.

- Performance Trade-Offs:

Balancing Strength and Flexibility: Enhancing strength and durability often comes at the expense of flexibility and elasticity, requiring a careful balance based on application needs.

Limited Elastic Recovery: The reinforced structure might not recover its original shape as effectively after deformation, which can be a disadvantage in applications requiring repeated bending or stretching.

- Availability:

Supply Chain Issues: Sourcing specific reinforcing materials (e.g., Kevlar, steel wire) can be challenging, leading to potential supply chain issues or delays.

Customization Lead Time: Custom orders may have longer lead times due to the specific manufacturing processes involved in adding fabric inserts.

- Maintenance and Durability:

Inspection and Maintenance: The durability of insertion natural rubber may reduce maintenance frequency, but when maintenance is required, it can be more complex due to the reinforced structure.

Failure Points: If the reinforcing material or the bond between the rubber and the reinforcement fails, it can lead to performance issues or premature failure.

- Environmental Impact:

Sustainability Concerns: The production and disposal of insertion natural rubber, especially with synthetic reinforcements, may raise environmental concerns. The use of non-biodegradable materials like polyester and nylon adds to the environmental footprint.

Need Guidance on Insertion Natural Rubber?

Stephens Gaskets is a leading supplier of high-quality Insertion Natural Rubber. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Insertion Natural Rubber and how we can help you with your next project.