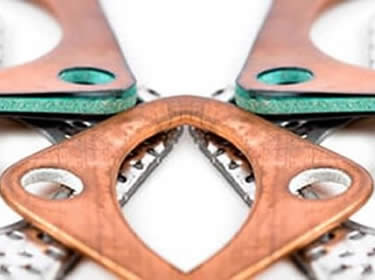

Expanded PTFE Seals

Expanded PTFE Seals: Reliable, High-Performance Sealing for Industrial Applications

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Industries such as chemical processing, pharmaceuticals, oil and gas, food production, and power generation require seals that can withstand extreme temperatures, aggressive chemicals, and high-pressure conditions. Standard gaskets and rubber seals often degrade under these conditions, leading to leaks, inefficiencies, and costly maintenance.

Expanded PTFE (ePTFE) seals are designed to address these challenges, offering exceptional chemical resistance, durability, and adaptability. At Stephens Gaskets, we manufacture high-performance expanded PTFE seals that provide long-lasting, leak-free solutions for demanding applications.

Call us: +44 (0)121 544 5808

Email us: sales@stephensgaskets.co.uk

What Are Expanded PTFE Seals?

Expanded PTFE (Polytetrafluoroethylene) seals are engineered for superior performance, offering chemical resistance, thermal stability, and flexibility for industrial sealing. Unlike standard PTFE, expanded PTFE is mechanically processed to create an interlocking fibrous microstructure, enhancing its compressibility, adaptability, and sealing properties.

- Resistant to aggressive acids, solvents, and hydrocarbons

- Performs in extreme temperatures from -200°C to +260°C

- Highly flexible, ensuring a tight seal on rough or irregular surfaces

- Minimal creep and cold flow, ensuring long-term performance

- FDA-approved for food and pharmaceutical applications

Why Choose Expanded PTFE Seals?

1. Universal Chemical Compatibility

- Withstands exposure to strong acids, alkalis, solvents, and petroleum-based fluids

- Ideal for highly aggressive chemical environments

2. Handles Extreme Temperature Conditions

- Maintains flexibility at cryogenic temperatures as low as -200°C

- Performs in high-temperature applications up to +260°C, suitable for steam, gas, and heated fluid systems

3. Excellent Flexibility and Adaptability

- Conforms to uneven, rough, or damaged sealing surfaces for a tight, leak-free seal

- Expands to accommodate flange misalignment and surface imperfections

4. Low Creep and Cold Flow Resistance

- Maintains dimensional stability under constant pressure and temperature variations

- Prevents gasket relaxation, ensuring a reliable long-term seal

5. FDA-Approved and Hygienic

- Complies with food-grade and pharmaceutical safety standards

- Non-toxic and non-contaminating, making it ideal for hygiene-sensitive applications

6. Cost-Effective and Maintenance-Free

- Long-lasting performance reduces downtime and replacement costs

- Prevents leaks and inefficiencies, lowering operational expenses

Where Are Expanded PTFE Seals Used?

- Seals flanges, pipelines, pumps, and valves in corrosive chemical environments

- Withstands highly aggressive acids, alkalis, and industrial solvents

- Provides leak-free sealing in oil refineries, offshore platforms, and petrochemical plants

- Handles high-pressure and high-temperature exposure

- FDA-approved for food and hygiene-critical applications

- Used in sanitary processing lines, cleanrooms, and food manufacturing equipment

- Seals used in boilers, steam systems, and heat exchangers

- Resistant to high pressure and thermal cycling in nuclear, gas, and coal-fired power plants

- Provides reliable sealing in engines, hydraulic systems, and exhaust components

- Resists temperature extremes, vibration, and exposure to fuels and lubricants

- Seals pumps, valves, and filtration systems in municipal and industrial water treatment plants

- Resists exposure to chlorine, acids, and treatment chemicals

- Prevents leaks in compressors, ventilation systems, and heat exchangers

- Enhances system efficiency by reducing maintenance needs

Contact our experts today: +44 (0)121 544 5808

Common Challenges and Solutions for Expanded PTFE Seals

Higher Initial Cost

- Challenge: This PTFE seals cost more than traditional rubber or fiber gaskets

- Solution: Their long lifespan, superior performance, and reduced maintenance needs make them a cost-effective investment over time

Sensitivity to Over compression

- Challenge: Excessive bolt torque can deform the material

- Solution: Use precise torque settings during installation for optimal performance

Not Suitable for Extremely High-Pressure Environments

- Challenge: While effective in moderate-pressure applications, ePTFE may not withstand ultra-high pressures

- Solution: For extreme pressure applications, use reinforced PTFE or metal-reinforced gaskets

Requires Proper Surface Preparation

- Challenge: Works best on clean, smooth flange surfaces

- Solution: Ensure proper flange preparation and alignment to maximise sealing efficiency

Selecting the Right Expanded PTFE Seal for Your Needs

To ensure the best performance, consider:

- Operating temperature range (-200°C to +260°C)

- Chemical exposure (acids, solvents, hydrocarbons)

- Flange condition (smooth vs. rough or irregular surfaces)

- Pressure requirements (low to moderate pressure applications)

Contact Us for custom sealing solutions tailored to your application.

FAQs

What makes expanded PTFE different from standard PTFE?

Expanded PTFE has a fibrous microstructure, making it more flexible and adaptable for sealing irregular surfaces compared to standard PTFE.

Can these PTFE seals withstand high pressure?

Yes, but they are best suited for moderate-pressure applications. For extremely high-pressure environments, consider reinforced PTFE or metal gaskets.

Are expanded PTFE seals safe for food and pharmaceutical use?

How long do expanded PTFE seals last?

How do I install expanded PTFE seals correctly?

Call us today for expert guidance: +44 (0)121 544 5808

Why Choose Stephens Gaskets for Expanded PTFE Seals?

- Decades of experience in precision gasket manufacturing

- Custom sizing and bulk production capabilities

- Fast turnaround times and expert technical support

- Seals compliant with industry safety and quality standards