CS80 Spring Steel Washers

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for CS80 Spring Steel Washers

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Global Leaders in Shim Solutions

As a trusted provider of shim solutions, we serve OEMs and businesses globally.

At Stephens Gaskets, we are a proud supplier of CS80 Spring Steel Washers that can be custom made to meet the needs of our customers. Moreover, our experienced team is equipped with the latest technology and machinery to manufacture high-quality CS80 Spring Steel Washers that are built to last.

If you’re seeking high-quality CS80 Spring Steel Washers with a quick turnaround, look no further.

Our reputation as the best in the business is well-deserved. With over 70 years of experience delivering top-notch products that meet both your budget and timeline. Our commitment to quality and efficiency is unwavering.

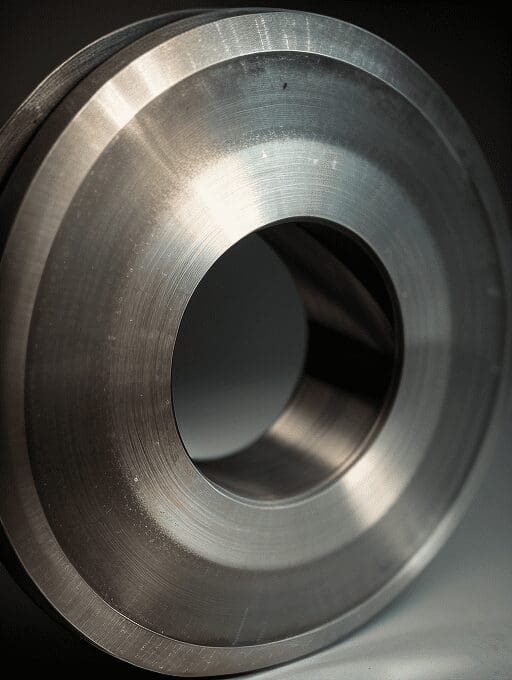

What are CS80 Spring Steel Washers?

CS80 Spring Steel Washers are specialised washers made from CS80 grade spring steel, known for their excellent hardness, strength, and durability. These washers are typically used in applications requiring high levels of resistance to deformation and wear.

Key Details of CS80 Spring Steel Washers

Material Quality:

Made from CS80 grade spring steel, known for its high carbon content, which provides superior strength and hardness.

High Load Capacity:

Designed to withstand high levels of stress and maintain their shape, making them ideal for applications with heavy loads.

Durability:

Excellent wear resistance, ensuring a long service life even under harsh conditions.

Elasticity:

The spring steel material allows the washers to absorb shock and vibrations, providing a cushioning effect.

Common Uses

Automotive Industry:

Used in suspension systems, brakes, and clutches.

Machinery:

Essential in various types of machinery to distribute loads and reduce wear on components.

Construction:

Utilised in structural applications to provide stability and resistance to dynamic loads.

Aerospace:

Critical in high-stress aerospace applications due to their reliability and strength.

Why Choose Zintec Copper Washers?

Choosing Zintec copper washers can enhance the longevity and performance of your assemblies. Their unique composition offers a balance of strength, conductivity, and corrosion resistance that is hard to find in other materials. Whether you’re dealing with high temperatures, electrical currents, or corrosive environments, these washers provide reliable performance and peace of mind.

Benefits of CS80 Spring Steel Washers

High Load-Bearing Capacity

Strength: CS80 spring steel washers can withstand significant stress and load without deforming, making them ideal for applications involving heavy loads and high-pressure conditions.

Superior Durability

Longevity: The high carbon content of CS80 spring steel provides exceptional hardness and strength, resulting in excellent wear resistance and ensuring a long service life even in demanding environments.

Elasticity and Flexibility

Shock Absorption: The inherent properties of spring steel allow these washers to absorb shock and vibrations effectively, maintaining the integrity of mechanical assemblies and preventing damage to connected components.

Corrosion Resistance

Protection: CS80 spring steel washers often undergo treatments that enhance their resistance to corrosion, making them suitable for use in environments exposed to moisture and other corrosive elements.

Consistent Performance

Reliability: These washers provide reliable and consistent performance under varying conditions, maintaining their shape and functionality over time for stable and dependable operation of assemblies.

Cost-Effective Solution

Savings: The durability and long lifespan of CS80 spring steel washers lead to reduced maintenance and replacement costs. Their robust nature means fewer interruptions and downtime, translating to cost savings in the long run.

Versatility

Adaptability: CS80 spring steel washers are suitable for a wide range of applications across different industries, including automotive, aerospace, machinery, and construction. Their robust properties make them adaptable to various uses.

Enhanced Safety

Stability: By evenly distributing loads and reducing the risk of component failure, these washers enhance the overall safety of mechanical assemblies, particularly important in critical applications where reliability is paramount.

Looking for a CS80 Spring Steel Washers Supplier?

Stephens Gaskets is a leading supplier of high-quality CS80 Spring Steel Washers. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our CS80 Spring Steel Washers and how we can help you with your next project.

Applications of CS80 Spring Steel Washers

Automotive Industry

- Suspension Systems: Used to provide stability and absorb shocks in vehicle suspension systems.

- Braking Systems: Ensures the reliability and efficiency of brakes by evenly distributing pressure and reducing wear.

- Clutches: Helps in maintaining the alignment and smooth operation of clutch assemblies.

Machinery and Equipment

- Heavy Machinery: Essential in heavy-duty machinery for distributing loads and minimising wear on moving parts.

- Industrial Machines: Used in various types of industrial equipment to enhance durability and performance.

- Agricultural Equipment: Ensures the longevity and reliability of farming machinery under heavy use.

Construction and Infrastructure

- Structural Applications: Used in building structures to provide stability and support, especially in dynamic load conditions.

- Bridges and Railways: Ensures the integrity and safety of bridges and railway systems by absorbing vibrations and shocks.

Aerospace Industry

- Aircraft Assemblies: Critical in maintaining the safety and performance of aircraft by withstanding extreme conditions and loads.

- Spacecraft Components: Used in spacecraft where reliability and durability are paramount under harsh environmental conditions.

Marine Industry

- Boat and Shipbuilding: Provides resistance to corrosion and ensures the durability of marine structures and components.

- Offshore Structures: Used in offshore platforms and installations where exposure to moisture and corrosive elements is high.

Electronics and Electrical Applications

- Circuit Boards: Ensures secure and stable connections in electronic assemblies.

- Electrical Equipment: Used in various electrical components to provide durability and reliability.

General Industrial Applications

- Pumps and Valves: Ensures the efficient operation of pumps and valves by maintaining alignment and reducing wear.

- Fastening Systems: Used in fastening applications to distribute load evenly and prevent loosening.

Renewable Energy

- Wind Turbines: Ensures the reliability and longevity of wind turbine assemblies by withstanding dynamic loads and harsh conditions.

- Solar Panel Mounting Systems: Provides stability and durability to solar panel installations.

Industry-Specific (Manufacturing) Material Recommendations for CS80 Spring Steel Washers

CS80 Spring Steel Washers are known for their high strength, durability, and ability to withstand significant stress and wear. Different manufacturing industries may have specific requirements and recommendations for these washers based on their unique applications and environmental conditions.

1. Automotive Industry

- Material Coating: Consider using zinc or phosphate coatings for corrosion resistance.

- Heat Treatment: Recommend heat-treated CS80 steel for enhanced strength and fatigue resistance.

- Surface Finish: Smooth or polished surface finishes to reduce friction and wear in dynamic applications.

2. Aerospace Industry

- Precision Manufacturing: Ensure tight tolerances and high precision in manufacturing to meet stringent aerospace standards.

- Heat Resistance: Utilise materials treated for enhanced heat resistance to withstand high-temperature environments.

3. Construction Industry

- Galvanised Coating: Hot-dip galvanising can provide excellent corrosion resistance for outdoor and structural applications.

- Heavy-Duty Design: Use thicker and more robust designs to handle heavy loads and structural stress.

- UV Resistance: Consider UV-resistant coatings for applications exposed to direct sunlight.

4. Marine Industry

- Stainless Steel Coating: Use stainless steel coatings or duplex stainless steel for superior resistance to saltwater and marine environments.

- Anti-Corrosion Treatment: Apply anti-corrosion treatments to enhance longevity in harsh marine conditions.

- High Toughness: Ensure the material has high toughness to withstand impact and stress from waves and currents.

5. Electronics and Electrical Industry

- Non-Conductive Coating: Use non-conductive coatings to prevent electrical interference and short circuits.

- Miniaturisation: Manufacture washers with precise dimensions for use in compact electronic assemblies.

- Thermal Stability: Ensure thermal stability to prevent degradation under varying electrical loads.

6. General Manufacturing and Heavy Machinery

- Wear-Resistant Coatings: Apply wear-resistant coatings like nitride or carbide for applications involving heavy abrasion and wear.

- Lubrication: Consider self-lubricating coatings to reduce friction and wear in moving parts.

- High Load Capacity: Design washers to meet specific load requirements, ensuring they can handle the stress of heavy machinery.

7. Renewable Energy Industry

- Environmental Resistance: Use materials and coatings that can withstand exposure to varying environmental conditions, such as moisture and temperature fluctuations.

- Fatigue Resistance: Ensure high fatigue resistance to handle the cyclic loads of wind turbines and solar panel systems.

- Eco-Friendly Coatings: Opt for environmentally friendly coatings that do not compromise performance or durability.

Key Considerations Across Industries:

- Material Selection: Ensure that CS80 spring steel meets industry standards and specifications for strength, hardness, and durability.

- Surface Treatments: Apply appropriate surface treatments and coatings to enhance performance based on environmental exposure and application needs.

- Quality Control: Implement rigorous quality control measures to ensure consistency and reliability of the washers.

By tailoring the material recommendations to the specific requirements of each industry, CS80 Spring Steel Washers from Stephens Gaskets can provide optimal performance, reliability, and longevity in a wide range of applications. Contact Us to discuss your industry-specific needs and find the best solutions for your manufacturing processes.

FAQs

What are the common uses of spring steel washers?

Spring steel washers are commonly used in automotive, aerospace, machinery, construction, and marine industries to provide stability, distribute loads, and absorb shock and vibrations.

Why are spring steel washers important in mechanical assemblies?

Spring steel washers are crucial for ensuring the integrity and reliability of mechanical assemblies by evenly distributing loads, reducing wear, and absorbing shocks and vibrations.

What are the best practices for installing and maintaining CS80 spring steel washers?

Best practices include using proper installation tools and techniques, following clear installation guidelines, and performing regular maintenance checks to ensure optimal performance.

Are there industry-specific certifications or standards for CS80 spring steel washers?

Yes, CS80 spring steel washers can be manufactured to meet various industry-specific certifications and standards, ensuring they meet the stringent requirements of different applications.

What is the warranty and return policy for CS80 spring steel washers?

Stephens Gaskets provides a warranty on all products, ensuring quality and performance. Our customer support team is available to assist with any issues or questions you may have regarding returns or replacements.

How can I place an order for CS80 spring steel washers and what are the delivery options?

To place an order, contact Stephens Gaskets directly. We offer various delivery options to meet your needs, including expedited shipping for urgent orders.

Need Guidance on CS80 Spring Steel Washers?

Stephens Gaskets is a leading supplier of high-quality CS80 Spring Steel Washers. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our CS80 Spring Steel Washers and how we can help you with your next project.