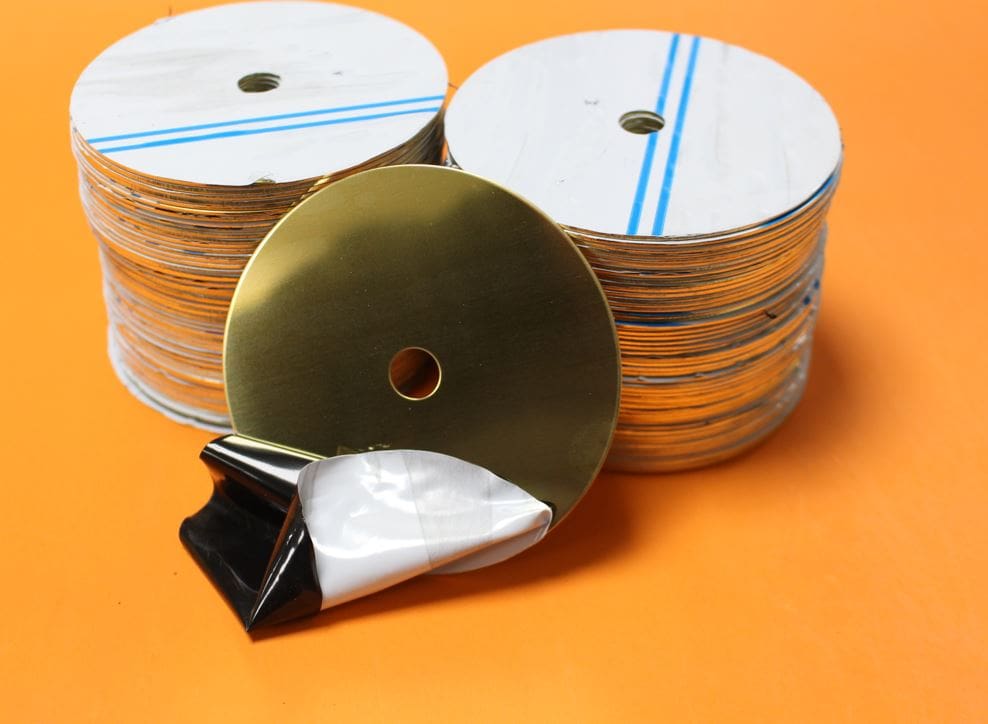

Brass CW508L – CZ108 H/H

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for CS80 Spring Steel Washers

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Global Leaders in Shim Solutions

As a trusted provider of shim solutions, we serve OEMs and businesses globally.

At Stephens Gaskets, we are a proud supplier of Brass CW508L – CZ108 H/H that can be custom made to meet the needs of our customers. Moreover, our experienced team is equipped with the latest technology and machinery to manufacture high-quality Brass CW508L – CZ108 H/H that are built to last.

If you’re seeking high-quality Brass CW508L – CZ108 H/H with a quick turnaround, look no further.

Our reputation as the best in the business is well-deserved. With over 70 years of experience delivering top-notch products that meet both your budget and timeline. Our commitment to quality and efficiency is unwavering.

What is Brass CW508L – CZ108 H/H?

Brass CW508L, often referred to as CZ108 H/H, is a type of brass alloy commonly used for various industrial and manufacturing applications.

Key Details of Brass CW508L – CZ108 H/H:

- Composition and Characteristics: Brass CW508L (CZ108) is a high-grade brass alloy consisting primarily of copper and zinc. Additionally, this particular type of brass is known for its excellent cold working properties. It is classified as a “half-hard” brass, indicated by the “H/H” in its name, which means it has been work-hardened to a medium strength. Furthermore, this makes it more durable and resistant to wear compared to softer brasses.

- Applications: This alloy is particularly favoured for its good corrosion resistance and excellent formability, making it ideal for fabrication processes such as bending and drawing. Common applications include:

Architectural and Decorative Components: Due to its bright gold-like appearance, it is often used in fixtures, fittings, and decorative elements.

General Engineering Parts: Components that require moderate strength and high corrosion resistance, such as fasteners, hinges, and brackets.

Electrical Components: Its excellent conductivity makes it suitable for connectors and terminals in electrical assemblies.

Brass CW508L – CZ108 H/H is versatile, reliable, and commonly used where both aesthetics and mechanical resilience are important. Therefore, if you’re considering this material for your project or product, it offers a balanced mix of workability, durability, and visual appeal.

Benefits of Brass CW508L – CZ108 H/H

Brass CW508L – CZ108 H/H serves as a versatile material choice across various industries, including architectural design, general engineering, and electrical component manufacturing. Its durability, workability, and aesthetic qualities meet a wide range of requirements.

Excellent Formability

Cold Working: This alloy is well-known for its excellent cold working properties, making it suitable for forming processes such as bending, drawing, and rolling without the risk of cracking. Also, this property allows for the creation of complex shapes and designs, which is particularly beneficial in decorative architectural applications.

Good Corrosion Resistance

Durability: Brass CW508L – CZ108 H/H exhibits good resistance to corrosion, making it suitable for use in environments where moisture or corrosive elements are present. Additionally, this characteristic extends the life of products made from this alloy and reduces maintenance costs over time.

High Machinability

Efficiency: Despite being a half-hard brass, CZ108 still maintains good machinability. Similarly, this means it can be easily and efficiently cut, drilled, or machined into desired forms, which is advantageous in manufacturing settings where precision and ease of fabrication are required.

Aesthetic Appeal

Appearance: With its bright, gold-like finish, this brass alloy offers a visually appealing look that does not tarnish easily. This makes it an ideal choice for decorative elements in architectural designs, such as fixtures, fittings, and trims.

Non-Magnetic Properties

Non-Ferrous: Being a non-ferrous metal, CZ108 does not exhibit magnetic properties. This feature is crucial for applications that require non-magnetic materials, such as in electrical and electronic equipment.

Good Thermal & Electrical Conductivity

Conductivity: The high copper content in Brass CW508L – CZ108 H/H provides good thermal and electrical conductivity, making it suitable for use in electrical components and heat exchangers.

Looking for a Brass CW508L – CZ108 H/H Supplier?

Stephens Gaskets is a leading supplier of high-quality Brass CW508L – CZ108 H/H. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Brass CW508L – CZ108 H/H and how we can help you with your next project.

Applications of Brass CW508L – CZ108 H/H

Architectural & Decorative Elements

Fixtures and Fittings: Thanks to its bright, gold-like finish, CZ108 is often used in decorative architectural applications. It is ideal for door handles, trim, fittings, and other fixtures where appearance is important alongside durability.

General Engineering Components

Hardware: Its strength and corrosion resistance make it suitable for manufacturing various engineering parts. These include fasteners, hinges, brackets, and small hardware where moderate strength and resistance to weathering are required.

Electrical Components

Conductive Parts: The good electrical conductivity of brass makes CZ108 a good choice for electrical applications. It is used in the manufacture of connectors, terminals, and switches where non-magnetic, conductive properties are essential.

Consumer Goods

Decorative Items: Brass CZ108 is also utilised in the production of consumer goods such as costume jewellery, musical instruments (especially brass wind instruments), and decorative items that benefit from its aesthetic quality and ease of fabrication.

Industrial Applications

Heat Transfer Components: In industries, this brass alloy is used for making radiator cores and tubes, heat exchangers, and other components that require excellent heat transfer properties.

Plumbing Fixtures

Water-Resistant Parts: Its corrosion resistance makes it a practical choice for plumbing applications, including faucet components and other fixtures exposed to water.

Industry-Specific (Manufacturing) Material Recommendations for CS80 Spring Steel Washers

If you’re in the manufacturing sector and considering or using Brass CW508L (CZ108 H/H), follow these industry-specific material recommendations to ensure optimal performance and efficiency. Here’s a detailed guide to handling and working with this brass alloy effectively:

Material Handling and Storage:

- Avoid Corrosion: Store brass sheets or components in a dry environment to prevent tarnishing and corrosion. Use protective coatings or oils if long-term storage is necessary.

- Stacking: Use padding between sheets when stacking to prevent surface damage.

Machining Recommendations:

- Tooling: Use sharp, carbide-tipped tools for machining to maintain clean cuts and prolong tool life.

- Coolants: Employ water-soluble coolants to enhance tool life and surface finish. Also, this helps in reducing heat build-up during machining.

- Speeds and Feeds: Optimal machining requires moderate speeds and light-to-medium feeds to balance machinability with tool wear.

Forming and Bending:

- Annealing: If deep drawing or severe bending is required, anneal the brass between operations to avoid work hardening and cracking.

- Bending Radius: Use a bending radius of at least the material thickness to prevent cracking during forming operations.

Welding and Joining:

- Brazing and Soldering: Brass CW508L is well-suited for brazing and soldering; however, proper fluxes must be used to avoid zinc evaporation and porosity in the joint.

- Welding: While welding is less common with brass due to the risk of zinc loss, techniques like TIG welding can be used with appropriate zinc-rich filler materials.

Finishing Processes:

- Polishing: Brass CZ108 polishes well to a bright finish, which is ideal for decorative applications. Regular polishing maintenance can also help prevent tarnish.

- Plating and Coating: To enhance corrosion resistance or to alter the appearance, brass can be plated with materials like nickel or chrome, or coated with clear lacquers.

Corrosion Prevention:

- Environmental Considerations: In environments prone to corrosion, especially marine or highly acidic environments, it may be necessary to select a more corrosion-resistant alloy or apply protective coatings.

Recycling Practices:

- Scrap Management: Brass is highly recyclable, so ensure efficient scrap collection and management practices to reduce waste and recover costs.

In summary, manufacturers can maximise the benefits of Brass CW508L (CZ108 H/H) by adhering to these recommendations, ensuring durability, workability, and aesthetic quality, while effectively managing production costs and environmental impacts.

FAQs

How does Brass CW508L – CZ108 H/H compare to other brass alloys like CZ106?

Brass CW508L – CZ108 H/H offers superior cold working properties and corrosion resistance compared to some other brass alloys like CZ106. Furthermore, it is particularly well-suited for applications requiring good formability and a bright finish.

What are the machining properties of CZ108?

CZ108 is known for its good machinability, allowing it to be easily and efficiently cut, drilled, or machined into desired forms. Additionally, this makes it advantageous in manufacturing settings where precision and ease of fabrication are required.

Where can I order Brass CW508L – CZ108 H/H?

You can order Brass CW508L – CZ108 H/H from Stephens Gaskets, a reputable supplier offering high-quality brass alloys tailored to your specific requirements.

What is the lead time for delivering CZ108 sheets?

The lead time for delivering CZ108 sheets can vary based on order volume and customisation requirements. Contact Us for detailed information on delivery times and to discuss your specific needs.

Are there any bulk discount options available for CZ108?

Yes, Stephens Gaskets offers bulk discount options for large orders of Brass CW508L – CZ108 H/H. Contact our sales team to discuss pricing and bulk order options.

Need Guidance on Brass CW508L – CZ108 H/H?

Stephens Gaskets is a leading supplier of high-quality Brass CW508L – CZ108 H/H. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. In addition, we commit ourselves to providing top-notch products and services for companies nationwide.

Get in touch with us today to learn more about our Brass CW508L – CZ108 H/H and how we can help you with your next project.