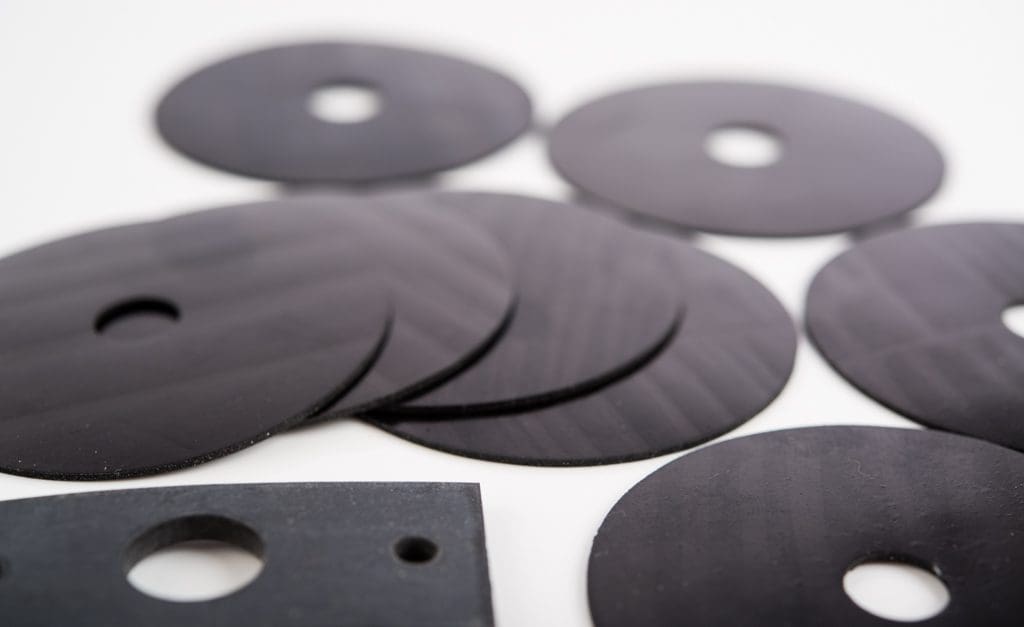

Round rubber washers and rubber washers in general are essential components in various industries due to their versatility and durability. These flat rubber circles with a hole in the middle accommodate fasteners or allow fluids to flow through, making them ideal for preventing leaks, protecting surfaces, and reducing vibrations. Their flexibility and resilience make rubber washers superior to metal washers in many applications, particularly in plumbing, HVAC systems, and any setting involving water contact. Additionally, rubber washers insulate against electric charges in electronic and thermal applications.

3 Types of Rubber Washers and Their Benefits

Different types of rubber washers cater to specific needs, providing unique advantages based on their material properties. Here are the three main types of rubber washers offered by Stephens Gaskets:

1. Silicone Washers Silicone washers excel in extreme temperatures, both hot and cold, and perform well in dry or humid climates. They offer low compression sets and resist elements like UV light and fungus, making them ideal for various challenging environments.

2. Ethylene Propylene Diene Monomer (EPDM) Rubber Washers EPDM washers withstand extreme temperatures and resist ozone, steam, water, alcohols, and brake fluids. They have low gas permeability and dielectric qualities, offering protection from electrical currents. EPDM also boasts excellent heat resistance and color stability.

3. Neoprene Rubber Washers Neoprene washers are known for their resistance to oils, petroleum, solvents, freons, high-aniline point oils, and mild acids. They perform well in general-purpose elastomer applications, making them versatile and reliable for many uses.

Rubber Washer Applications

Rubber washers serve a wide range of purposes, including:

- Spacers: Fill gaps between components to ensure proper alignment and spacing.

- Springs: Absorb shock and reduce vibrations in machinery.

- Locking Devices: Secure fasteners and prevent them from loosening.

- Wear Pads: Protect surfaces from abrasion and damage.

- Seals: Prevent fluid leaks in plumbing and other systems.

Industries that commonly use rubber washers include construction, electrical and plumbing installation, aerospace, automotive manufacturing, appliance production, and OEMs. Their ability to absorb vibrations helps extend the operational lifespan of machinery, ensuring smoother performance and reducing maintenance needs.

Custom-Designed Rubber Washers

Stephens Gaskets offers a wide range of standard and custom-designed rubber washers. Our bespoke service caters to specific requirements, ensuring that you get the perfect mechanical solution for your application. Whether you need a specific size, shape, or material, we have the expertise and resources to deliver high-quality, tailored products.

Contact Stephens Gaskets Today

For more information about our round rubber washers, visit our website or call 0121 544 5808 to speak with one of our shim experts. We offer quick turnarounds and competitive pricing to ensure your business operations run smoothly.

If you found this blog helpful, you may also want to read our guide to silicone rubber washers.