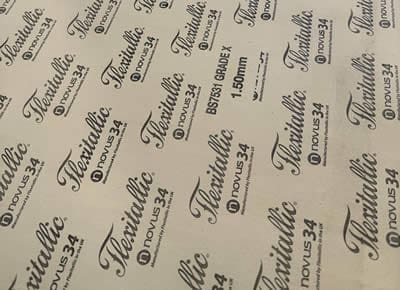

BS7531 Grade Sheeting

BS7531 Grade X Non-Asbestos Fibre Sheeting – The Ultimate Sealing Solution

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What is BS7531 Grade X Non-Asbestos Fibre Sheeting?

BS7531 Grade X Non-Asbestos Fibre Sheeting is an industrial-grade sealing material that meets British Standard BS7531 Grade X. Made from aramid, mineral, and glass fibres bonded with a rubber binder (NBR), this composite sheet provides outstanding mechanical, thermal, and chemical resistance.

Key Benefits:

- Asbestos-Free & Safe: Meets modern health & safety regulations.

- High-Temperature Resistance: Withstands up to 400°C.

- Exceptional Chemical Resistance: Protects against steam, fuels, oils & acids.

- Superior Sealing Performance: Ensures tight, long-lasting seals.

- Reliable Under Pressure: Handles dynamic loads & thermal cycling.

Why Choose BS7531 Grade X Non-Asbestos Fibre Sheeting?

- Guaranteed compliance with BS7531 Grade X standards.

- Available in multiple thicknesses for custom applications.

- Minimises downtime with consistent, high-performance sealing.

Industry-Specific Materials Used in BS7531 Grade X Non-Asbestos Fibre Sheeting

BS7531 Grade X is a multi-layered composite material engineered for extreme durability and performance.

1. Aramid Fibres (Kevlar®)

- High tensile strength for maximum durability.

- Heat-resistant to prevent gasket degradation.

2. Mineral Fibres

- Provides dimensional stability & compressibility.

- Enhances resistance to mechanical stress.

3. Glass Fibres

- Improves flexibility & reinforcement.

- Ensures long-term reliability.

4. Nitrile Butadiene Rubber (NBR) Binder

- Creates a strong, flexible structure.

- Enhances chemical & oil resistance.

Applications of BS7531 Grade X Non-Asbestos Fibre Sheeting

BS7531 Grade X Non-Asbestos Fibre Sheeting is widely used across industries that require high-performance gaskets and sealing solutions.

- Flanged joints in pipelines, boilers & compressors.

- High-pressure sealing in steam, gas, and fluid applications.

- Thermal-resistant gaskets in extreme industrial environments.

- Critical sealing for turbines, power plants & chemical reactors.

- Protects against fuels, oils, acids & solvents.

- Ensures long-lasting performance in corrosive environments.

- Seals for high-temperature boilers, steam circuits & pumps.

- Maintains gasket integrity in harsh operating conditions.

- Available in sheets or pre-cut gaskets.

- Self-adhesive options for easier installation.

Common Challenges & How Stephens Gaskets Solves Them

While BS7531 Grade X Non-Asbestos Fibre Sheeting is a leading sealing solution, certain challenges must be addressed to maximise performance.

1. Precise Installation is Crucial

- Problem: Over-compression or under-compression can weaken the seal.

- Solution: Follow torque specifications & use pre-cut gaskets for consistent performance..

2. Higher Cost Compared to Standard Gaskets

- Problem: Premium materials cost more upfront.

- Solution: Longer lifespan & reduced maintenance costs make it a cost-effective investment.

3. Requires Specialised Cutting & Handling

- Problem: Harder to cut than standard gasket materials.

- Solution: Pre-cut gaskets & custom sizes available for convenience.

4. Performance Depends on Manufacturing Quality

- Problem: Inconsistent materials can affect sealing efficiency.

- Solution: Choose a trusted supplier like Stephens Gaskets for guaranteed quality.

Choosing the Right BS7531 Grade X Non-Asbestos Fibre Sheeting

When selecting the right material, consider:

- Temperature Range: Can withstand up to 400°C.

- Chemical Exposure: Resistant to steam, fuels, acids & oils.

- Pressure Conditions: Handles high-pressure applications.

- Installation Requirements: Available in sheets or custom-cut gaskets.

Our expert team can guide you through the selection process to ensure you get the best solution for your needs.

Why Choose Stephens Gaskets as Your Supplier?

- 70+ Years of Industry Experience – Trusted by leading industries.

- High-Quality Manufacturing – Fully compliant with BS7531 Grade X standards.

- Custom & Standard Sizes Available – Flexible solutions for any application.

- Fast UK & International Delivery – Minimise downtime with reliable supply.

- Dedicated Technical Support – Expert advice on material selection.

Order BS7531 Grade X Non-Asbestos Fibre Sheeting Today!

Offering premium sealing solutions for high-performance applications.

– Custom Orders Available: Tailored solutions for your sealing needs.

– Bulk Supply Options: Competitive pricing for high-volume orders