Precision Laser Cutting, Countersinking, Drilling, Tapping, and Metal Bending

Precision Laser Cutting, Countersinking, Drilling, Tapping, and Metal Bending Services at Stephens Gaskets

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Sets Stephens Gaskets Apart?

For over 70 years, Stephens Gaskets has provided precision metal components to industries across the UK and globally. Our state-of-the-art equipment and expert team ensure that every project is completed to the highest standards. We don’t just stop at cutting metal; we make sure it’s ready for assembly, shaped to perfection, and delivered on time.

Industries We Serve:

- Automotive

- Aerospace

- Manufacturing

- Construction

- Engineering

- Marine

Our Services

1. Laser Cutting

At the core of our offerings is laser cutting – a method that provides unrivalled precision and efficiency. Laser cutting is ideal for producing parts with complex shapes, intricate designs, and tight tolerances.

Our laser cutting services can handle various materials, including:

- Steel

- Aluminium

- Brass

- Copper

- Stainless Steel

We cut materials to bespoke sizes, creating everything from thin shims to larger, thicker components. Whether you need small-batch prototypes or large production runs, our advanced laser cutting technology guarantees precision every time.

Key Benefits of Our Laser Cutting Services:

- Unmatched precision: Ideal for tight tolerances and intricate designs.

- Fast turnaround: Whether you need a single part or thousands, we deliver quickly.

- Cost-effective: Reduced material wastage means you save on costs.

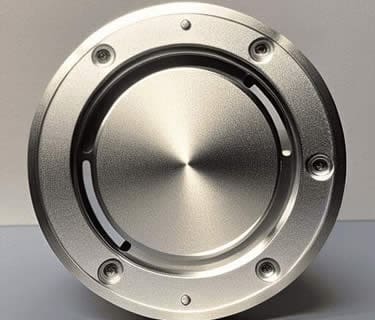

2. Countersinking, Drilling, and Tapping

Once your parts are laser-cut, they may require further processing to ensure smooth assembly. That’s where our countersinking, drilling, and tapping services come in.

Countersinking: This process allows us to create a cone-shaped hole that ensures your fasteners sit flush with the surface. Countersinking is essential for parts that require a smooth, flush finish, preventing protrusions that can cause alignment issues or damage.

Drilling: Need precise, clean holes in your components? Our drilling services guarantee accurate hole placement, diameter, and depth, ensuring your parts fit perfectly in their assembly.

Tapping: For parts that require threaded holes, our tapping service ensures precision threads that allow for easy, secure fastening. Tapping is essential for many industries, especially automotive, aerospace, and construction, where secure attachment points are critical.

Why Use Stephens Gaskets for Countersinking, Drilling, and Tapping?

- Accuracy: We ensure perfect hole placement, size, and depth.

- Efficiency: Integrated with our laser cutting services, these processes ensure quick, seamless production.

- Versatility: We handle various hole sizes and thread specifications to meet your project requirements.

3. Metal Folding and Bending

Bending and folding metal can be challenging, but with our CNC-controlled machines, we make it look easy. Our metal bending services are ideal for projects that require shaped metal without compromising the material’s integrity.

Folding and bending involve reshaping flat sheets into complex angles or curves, perfect for components that need to be shaped for specific assembly requirements.

Applications of Metal Bending and Folding:

- Automotive parts

- Aerospace components

- Construction brackets

- Architectural fittings

Using precision CNC equipment, we can guarantee that every bend and fold meets the exact specifications, whether you need sharp angles or smooth curves.

Advantages of Our Bending Services:

- Accuracy: Each bend is consistent and precise, with no deformation of the material.

- Versatility: We bend steel, aluminium, and other metals to your exact specifications.

- Efficiency: Our machines ensure repeatable accuracy, even for large volume runs.

Why Choose Stephens Gaskets?

FAQs About Nitrile Rubber BS2751 Gaskets

What types of materials can you work with?

What is the typical turnaround time for an order?

Do you offer prototype services?

Can you provide samples before committing to a full order?

How do your finishing services (countersinking, drilling, tapping) integrate with laser cutting?

Can I request custom bending or folding for complex shapes?

Conclusion

Ready to get started?

Whether you need laser cutting, countersinking, drilling, tapping, or metal bending, Stephens Gaskets is your trusted partner for precision and speed.