Die Cutting

Die Cutting Manufacturing Experts & Bespoke Specialists

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Die Cutting

Stephens Gaskets take great pride in what we do, including our die cutting services. Furthermore, since the 1940s we’ve been providing high quality services for individuals and businesses across the country. Over the years, we’ve expanded our repertoire to include many different skills. Therefore, we’re proud to be a forerunner in the business with a growing list of highly satisfied clients.

Decades of Experience

While we specialise in shims, washers and gaskets, we also offer first class services in cutting. Naturally, different products and machines require different types of cutting. Therefore, we offer a wide range of options using state of the art machinery. In addition to our decades of experience and expertise to make sure you receive the quality you need.

Ideal for Lower Strength Materials

The process dates back to the 19th century. It is used to shear flat webs of lower strength materials, ranging from paper to rubber, from leather to sheet metal. Over the years, as machinery has become more sophisticated, the possibilities available have increased significantly. As a result, we’re able to cut in ways that would have been unimaginable when this technique first arose, including die cutting.

Dedicated to Excellence

Shapes are die cut using flat bed tools to ensure a precise and uniform shape. Additionally, internal and external shapes are possible thanks to our skilled workers and dedication to excellence. Here at Stephens Gaskets, we are happy to provide excellent services for you or your business. We can ensure the consistency and precision you require for all of your needs.

But Why Choose Die Cutting?

It’s the perfect choice for those looking for regular re-orders. Especially for shapes which will not change, and need to be exactly the same each time. That’s why we recommend this service for those looking for a long run, with repeated orders, where exacting precision is required.

For Products Needing a Pristine Surface

It is also recommended for products which need to be pristine on the surface, without any sign of laser burn. Therefore, die cutting is best for those products which do not require a great deal of intricacy. This is because the minimum space between cuts is usually something around three millimetres. If you’re looking for something more intricate, we’d recommend looking into laser cutting as an alternative.

If you would like more information on our die cutting services please contact us on 0121 544 5808 OR visit our contact page here.

Die Cutting

Stephens Gaskets take great pride in what we do, including our die cutting services. Furthermore, since the 1940s we’ve been providing high quality services for individuals and businesses across the country. Over the years, we’ve expanded our repertoire to include many different skills. Therefore, we’re proud to be a forerunner in the business with a growing list of highly satisfied clients.

Decades of Experience

While we specialise in shims, washers and gaskets, we also offer first class services in cutting. Naturally, different products and machines require different types of cutting. Therefore, we offer a wide range of options using state of the art machinery. In addition to our decades of experience and expertise to make sure you receive the quality you need.

Ideal for Lower Strength Materials

The process dates back to the 19th century. It is used to shear flat webs of lower strength materials, ranging from paper to rubber, from leather to sheet metal. Over the years, as machinery has become more sophisticated, the possibilities available have increased significantly. As a result, we’re able to cut in ways that would have been unimaginable when this technique first arose, including die cutting.

Dedicated to Excellence

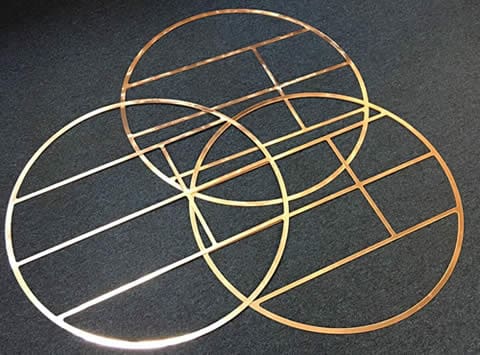

Shapes are die cut using flat bed tools to ensure a precise and uniform shape. Additionally, internal and external shapes are possible thanks to our skilled workers and dedication to excellence. Here at Stephens Gaskets, we are happy to provide excellent services for you or your business. We can ensure the consistency and precision you require for all of your needs.

But Why Choose Die Cutting?

It’s the perfect choice for those looking for regular re-orders. Especially for shapes which will not change, and need to be exactly the same each time. That’s why we recommend this service for those looking for a long run, with repeated orders, where exacting precision is required.

For Products Needing a Pristine Surface

It is also recommended for products which need to be pristine on the surface, without any sign of laser burn. Therefore, die cutting is best for those products which do not require a great deal of intricacy. This is because the minimum space between cuts is usually something around three millimetres. If you’re looking for something more intricate, we’d recommend looking into laser cutting as an alternative.

If you would like more information on our die cutting services please contact us on 0121 544 5808 OR visit our contact page here.