Technical Resources & Frequently Asked Questions

Custom Gaskets for Every Application

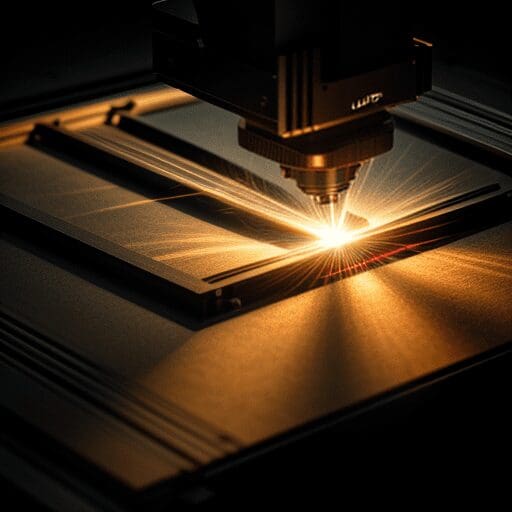

Stephens Gaskets is Your Reliable Supplier for Laser Cutting

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Welcome to your central hub for answers to common questions about our laser cutting capabilities, processes, and ordering logistics. Whether you are new to laser cutting or a seasoned professional, this page provides comprehensive technical resources and a detailed FAQ section to help you navigate our services. From technical specifications and lead times to customization options and support services, we cover everything you need to know to make informed decisions about your laser cutting projects.

Laser Cutting Capabilities

Laser cutting is a precise and versatile technology used to cut various materials into intricate shapes and designs. Our state-of-the-art laser cutting equipment allows us to handle a wide range of materials and thicknesses, ensuring high-quality outcomes for all your projects.

Materials We Can Cut:

- Metals: Steel, aluminium, stainless steel, copper, brass

- Plastics: Acrylic, polycarbonate, PETG, PVC

- Composites: Carbon fibre, fibreglass, MDF

Thickness Range:

- Metals: Up to 25 mm

- Plastics and Composites: Up to 20 mm

Precision and Accuracy:

- Our laser cutting technology offers high precision, with tolerances typically within ±0.1 mm. This ensures that each cut is accurate and consistent, meeting the exact specifications of your design.

Laser Cutting Processes

Understanding the laser cutting process can help you better prepare your designs and expectations. Here, we outline the key steps involved in laser cutting and how we ensure the highest quality results.

- Design Submission:

- Start by submitting your design files in a compatible format, such as DXF, DWG, or AI. Our team will review the files to ensure they are suitable for laser cutting.

- Material Selection:

- Choose the appropriate material for your project based on its properties, thickness, and suitability for laser cutting. Our experts can provide guidance on material selection to ensure optimal results.

- Cutting and Processing:

- Once the design and material are confirmed, we use computer-controlled laser cutting machines to execute the cuts. The precision of the laser ensures clean edges and accurate dimensions.

- Quality Control:

- After cutting, each piece undergoes a thorough quality control check to ensure it meets our high standards. We inspect for accuracy, consistency, and any potential defects.

- Packaging and Delivery:

- Finally, the completed parts are carefully packaged and prepared for delivery. We offer worldwide shipping to ensure your order reaches you promptly and in perfect condition.

Ordering Logistics

We aim to make the ordering process as smooth and straightforward as possible. Here are some key points to consider when placing an order with us:

Lead Times:

- Our standard lead times vary depending on the complexity and volume of the order. Typically, lead times range from 3 to 10 business days. For urgent projects, we offer expedited services to meet tight deadlines.

Customisation Options:

- We provide a range of customisation options to meet your specific needs. Whether you require unique shapes, sizes, or materials, our team can tailor our services to match your requirements.

Minimum Order Quantities:

- There are no strict minimum order quantities, allowing you to order as few or as many parts as you need. This flexibility ensures that both small-scale prototypes and large production runs are accommodated.

Payment and Invoicing:

- We offer various payment options, including credit card, bank transfer, and online payment portals. Invoicing is handled promptly, with detailed breakdowns of the services provided.

Comprehensive FAQ Section

Technical Specifications

What is the maximum thickness of material that can be laser cut?

For metals, we can cut up to 25 mm thick, while plastics and composites can be cut up to 20 mm thick.

What is the minimum feature size that can be laser cut?

The minimum feature size is typically 1 mm, ensuring precise and intricate designs can be achieved.

What are the tolerances for laser cutting?

Our standard tolerances are within ±0.1 mm, ensuring high precision and accuracy for all cuts.

Lead Times and Delivery

What are your standard lead times for laser cutting orders?

Standard lead times range from 3 to 10 business days, depending on the order’s complexity and volume.

Do you offer expedited services for urgent orders?

Yes, we provide expedited services to meet tight deadlines. Please contact us to discuss your specific requirements.

What is your worldwide delivery process?

We offer reliable worldwide shipping options to ensure your order arrives promptly and in excellent condition. Delivery times and costs will vary based on the destination.

Customisation Options

Can you produce custom shapes and sizes?

Yes, we specialise in producing custom shapes and sizes to meet your specific design requirements.

What materials can you customise for laser cutting?

We can customise a wide range of materials, including metals, plastics, and composites. Our team can help you select the best material for your project.

Do you offer prototyping services?

Yes, we offer prototyping services to help you test and refine your designs before full-scale production.

Support Services

How can I get technical support for my laser cutting project?

Our expert team is available to provide technical support and guidance throughout your project. Contact Us via phone, email, or our online chat service.

Do you provide design assistance?

Yes, we offer design assistance to ensure your files are optimised for laser cutting. Our team can help you with file preparation and design adjustments.

What is your return policy for laser cut parts?

We strive for 100% customer satisfaction. If you encounter any issues with your order, please contact us immediately, and we will work to resolve the problem.

Conclusion

Our comprehensive technical resources and FAQ section are designed to provide you with all the information you need to make the most of our laser cutting services. Whether you have questions about technical specifications, lead times, customization options, or support services, we are here to help.

Need Guidance on Laser Cutting?

Stephens Gaskets is a leading supplier of high-quality Laser Cutting. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Laser Cutting and how we can help you with your next project.