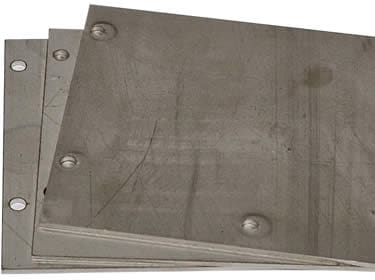

1.4003 / 3CR12 Stainless Steel

1.4003 / 3CR12 Stainless Steel: A Cost-Effective & Durable Solution

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Is 1.4003 / 3CR12 Stainless Steel?

1.4003 / 3CR12 is a utility-grade ferritic stainless steel that provides moderate corrosion resistance, durability, and affordability.

Designed as a cost-effective alternative to higher-grade stainless steels, it offers better performance than carbon steel while maintaining ease of fabrication and welding.

Key Properties of 1.4003 / 3CR12 Stainless Steel

- Corrosion Resistance: Performs well in mildly corrosive environments, resisting moisture, low chlorides, and industrial wear.

- Mechanical Strength: High toughness and impact resistance make it suitable for structural and load-bearing applications.

- Cost-Effective: Easily welded using standard techniques, with no post-weld heat treatment required for most applications.

- Weldability: More affordable than 304 or 316 stainless steel, offering a balance of performance and budget efficiency.

- Lightweight Alternative: Provides good strength-to-weight ratio, reducing structural load in transportation and construction.

Benefits of 1.4003 / 3CR12 Stainless Steel

1. Cost-Effective Alternative

- Lower cost than austenitic stainless steels (304, 316).

- Longer lifespan than carbon steel, reducing replacement costs.

2. Moderate Corrosion Resistance

- Performs well in mildly corrosive conditions, such as outdoor exposure, industrial environments, and damp locations.

- Less prone to rust than carbon steel but not ideal for high-chloride or marine environments.

3. High Strength & Durability

- Resists mechanical wear and abrasion, making it suitable for demanding environments.

- Performs well under impact and stress, ensuring long-term stability.

4. Easy Fabrication & Welding

- No post-weld heat treatment needed for most applications.

- Can be machined, cut, and bent easily for custom applications.

5. Sustainable & Recyclable

- Fully recyclable, contributing to environmentally friendly manufacturing.

- Long service life reduces waste and resource consumption.

6. Customisation for Industry Needs

- Available in various thicknesses, shapes, and finishes.

- Suitable for coating and surface treatments to enhance corrosion resistance.

Applications of 1.4003 / 3CR12 Stainless Steel

- Railway components: Used in rail carriages, underframes, and freight containers.

- Automotive parts: Ideal for exhaust systems, chassis components, and structural reinforcements.

- Roofing & cladding: Used in industrial and commercial buildings for its weather resistance.

- Bridges & walkways: Structural support components exposed to moisture and environmental stress.

- Storage tanks: Suitable for water, sewage, and chemical storage due to its moisture resistance.

- Pipework & filtration systems: Used in wastewater plants and clean water processing.

- Screens & wear plates: Applied in abrasion-prone mining equipment.

- Conveyor systems & hoppers: Ideal for handling bulk materials in mining and manufacturing.

- Coal chutes & hoppers: Withstands abrasion and thermal cycling in coal-fired power stations.

- Cooling systems: Used in power plant components exposed to humid conditions.

- Silos & grain storage: Protects against corrosion in agricultural applications.

- Food production equipment: Safe for non-critical food handling applications.

- Port infrastructure: Used in docks, fenders, and coastal structures.

- Shipbuilding: Suitable for non-critical marine components exposed to sea spray.

- Frames & supports: Common in machinery, equipment housing, and fabrication projects.

- Machinery components: Used in medium-duty industrial machines requiring moderate corrosion resistance.

Challenges & Solutions for 1.4003 / 3CR12 Stainless Steel

1. Lower Corrosion Resistance Than 304/316

- Challenge: Not suitable for marine environments or high-chloride exposure.

- Solution: Apply protective coatings or consider stainless steel upgrades for extreme conditions.

2. Aesthetic Limitations

- Challenge: Lacks the polished finish of higher-grade stainless steels.

- Solution: Can be surface-treated, brushed, or coated for improved aesthetics.

3. Limited High-Temperature Performance

- Challenge: Not recommended for applications above 600°C.

- Solution: For high-temperature applications, alternative stainless steel grades should be used.

4. Welding Considerations

- Challenge: Welding can weaken corrosion resistance in certain environments.

- Solution: Use correct filler materials and post-weld cleaning methods to prevent deterioration.

FAQs About 1.4003 / 3CR12 Stainless Steel

How does 1.4003 / 3CR12 compare to carbon steel?

Can 1.4003 / 3CR12 be used in marine environments?

What are the best applications for 1.4003 / 3CR12?

Can it be welded easily?

Do you offer custom sizes and bulk orders?

How quickly can I get my order?

Contact Us for a quote.