Summary. As a prominent shim washer manufacturer, Stephens Gaskets highlights the diverse uses of shim washers, especially in vehicle wheel alignment, canning in the food and drink industry, and pipeline applications. Their expertise in producing various types of shims, including aluminium and copper, caters to a wide range of industrial needs, ensuring safety, efficiency, and longevity in these sectors. Stephens Gaskets, with its bespoke service and ISO accreditation, stands as a reliable choice for high-quality shim washers.

The versatile nature of shim washers can optimise an array of applications, including those found in the manufacturing and automotive industries. While vehicle owners themselves are unaware of the benefits of wheel alignment, shim washers offer a new level of safety. As a leading shim washer manufacturer, we are fully knowledgeable of shim washers uses and advantages.

Here at Stephen’s Gaskets, we have been proud shim washer manufacturers since 1914 and are renowned for shim washers in the UK. Our extensive knowledge and experience make us specialists in our field. In today’s article, we’re going to focus on how shim washers can optimise applications found in a selection of major sectors.

Related: Different Types Of Shims | Getting The Right Shim For The Right Job

3 Uses For A Shim Washer

Shim Washers For Vehicles

The first example of the uses of a shim washer is in vehicles. An alignment shim, just one type of shim washer, can transform the performance of wheels. Misaligned wheels are extremely dangerous due to the loss of control in driving, and they can dramatically dampen the driving experience. This issue is found in all types of motors, not just those that are aged.

Like ourselves, shim washer manufacturers can produce alignment shims to the specific requirements of the vehicles you deal with. They align components to adjust the positioning of wheels. Therefore, ensuring your steering-to-mobility balance is enhanced. In further detail, the shim is inserted between the wheel hub and the car axle, where it then pushes forward on the hub and the wheel. Consequently, helping to reduce the metal distortion that has occurred.

Aluminium Shims For Food & Drink

As a shim washer manufacturer, we are met with a range of clients with various needs. For instance, those in the food and drink industry. Most commonly, our aluminium shims are sought after for canning. How are shims used in cans? Shims are known to prevent the aluminium’s reaction with the substances inside. Additionally, they allow for corrosion resistance, favoured by retail outlets and beyond.

Copper Shims For Pipelines

Another use for copper shim is for pipelines. Copper shims are renowned for their effectiveness in water transfer. As the copper exterior is a soft and ductile metal, it does not react with water. Therefore, pipelines can continue distributing water using the same copper components for many years. This is very much similar to the cabling system.

Related: Copper Shim – What Are The Benefits

Your First Choice Shim Washer Manufacturer

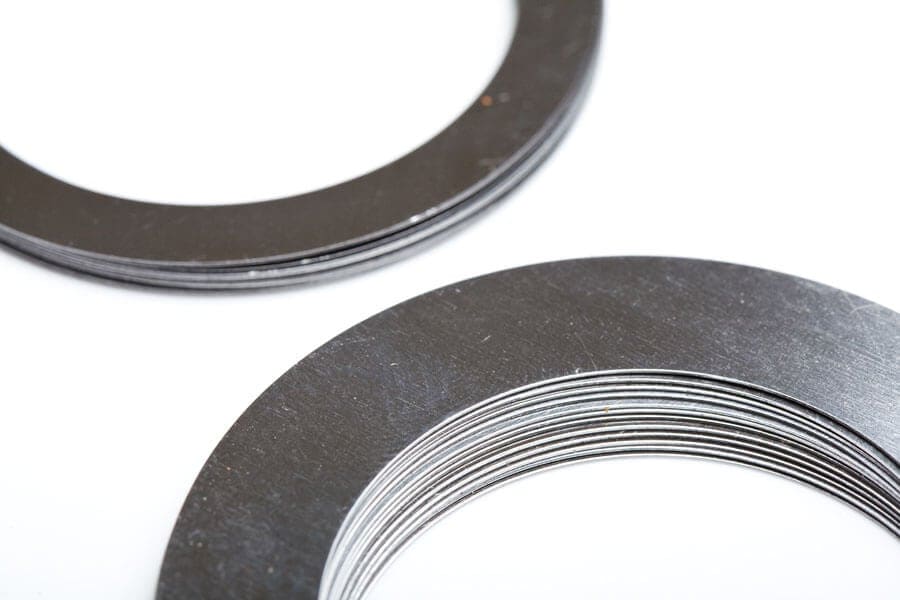

Here at Stephens Gaskets, we are a leading shim washer manufacturer. We have a host of shims available at Stephens Gaskets, including alignment, plastic, aluminium, brass, laminated and copper.

Additionally, our bespoke service gives us the ability to produce our shims in a range of sizes and a multitude of quantities to suit the needs of our clients. As an ISO accredited shim washer production company, we guarantee a safe, reliable and excellent service from concept to completion.

Get in touch with our happy and helpful team today on 0121 544 5808 for further information on how we can optimise your operations with immaculately produced shims. If you found this blog useful, why not take a look at a previous one: Why Use Brass Shim Washers?